FIBERTUBE

FIBERTUBE – Tube & Profile Laser Cutting Machine

Smart Precision for Tube & Profile Cutting

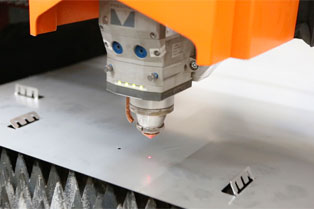

Engineered for today’s demanding production needs, FIBERTUBE is Ermaksan’s high-efficiency, fully automated fiber laser cutting solution for pipe and profile applications. With advanced technology and user-friendly automation, it redefines productivity in industries like automotive, furniture, agriculture, and defense.

FIBERTUBE effortlessly processes round, square, and rectangular tubes up to Ø150 mm and 7320 mm in length. It delivers outstanding precision for:

- Round tubes: Ø20–150 mm

- Square tubes: 20×20–140×140 mm

- Rectangular tubes: 20×30–100×150 mm

Its durable design features machine dimensions of 14850×5860×2600 mm and a total weight of 27,000 kg. It accommodates workpieces up to 4000 kg, with automatic loading lengths from 3000 to 7320 mm and a max unloading length of 4500 mm—perfect for heavy-duty processing.

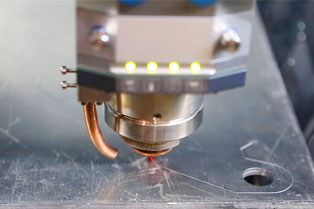

Powered by BECKHOFF CNC and servo motors, and equipped with the Precitec ProCutter 2.0 cutting head, FIBERTUBE ensures high-speed and high-precision cutting across 17 axes with 1G acceleration. It supports advanced software such as Lantek and Metalix (MTube) for seamless CAD/CAM integration and optimized cutting paths.

FIBERTUBE is the smart choice for manufacturers seeking flexibility, precision, and operational efficiency in high-volume pipe and profile cutting operations.

IN EVERY FIELD OF LIFE

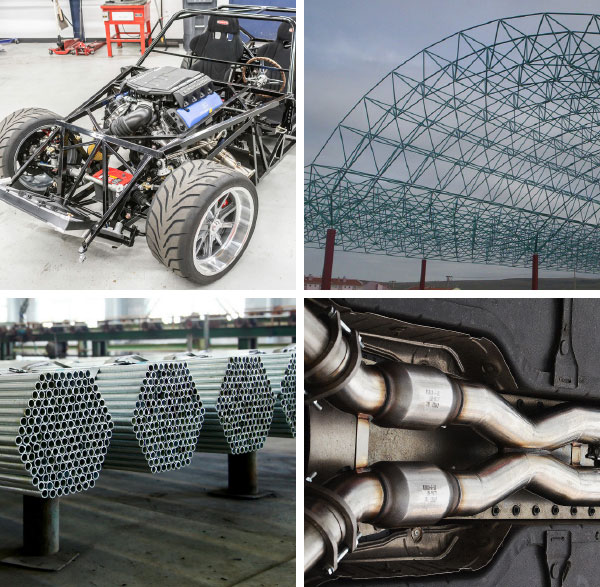

In today’s competitive world of manufacturing, precision and flexibility are not luxuries—they’re necessities. Ermaksan’s FIBERTUBE laser cutting machine is specifically designed to bring new levels of accuracy and adaptability to your production processes, whether in the defense industry, automotive sector, furniture making, or agriculture.

FIBERTUBE handles a wide variety of tubes and profiles with exceptional precision and gives life to your most ambitious designs. From the intricately cut metal components in your furniture to the electric poles lighting up your streets, from the product shelves in retail stores to the skeletal structures of bicycles, buses, cars, planes, and ships—laser-cut pipes and profiles shape the very world around us.

With FIBERTUBE, Ermaksan not only enhances your production efficiency but also empowers the value you deliver to your customers. Less waste, faster delivery, more elegant results—this is precision manufacturing redefined.

FLY-CUT FEATURE

With the Fly-Cut feature, you can cut both circular and equilateral pieces at great speeds with great quality.

PlayFREQUENCY CUTTING MODE

Thick material piercings are performed more quickly and heating of the material cut is prevented.

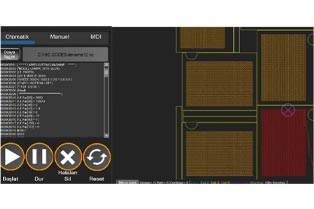

Read moreNC GRAPHICS AND REALTIME STREAMING

While the machine is cutting, it displays the 2D graphic of the NC code in color and allows you to follow which line of code it is on, all within a simple and user-friendly interface.

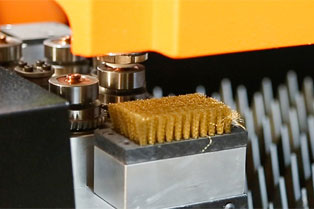

NOZZLE CLEANING / CALIBRATION

It is the process of autımatically cleaning the slag and dirt accumulated in the nozzle used with the nozzle cleaning system, offered in standard with Fibermak series lasers, by means of a cleaning brush.

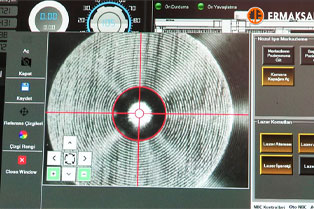

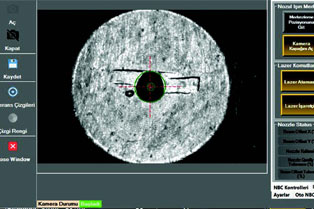

PlayBEAM CENTERING CAMERA

The camera-aided laser beam centering adjustment system enables the operators to adjust the laser center effortlessly when needed.

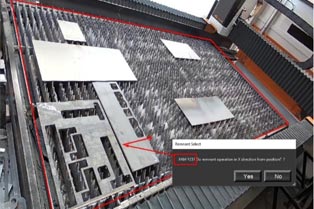

Read more PlayANTI CRASH SYSTEM

During cutting, possible collision between the laser cutting head and the displaced pieces is prevented, protecting the cutting head against damages.

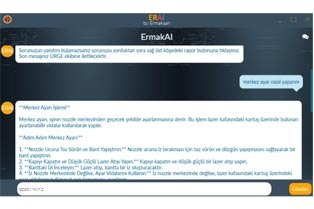

Read more PlayERAI - AI ASSISTANT

With ERAI - AI Assistant, discover features you didn't know about your machine, access solutions to errors, aand have a guide to show you the way.

Read moreCOUNTERSINK BY LASER

Thanks to Ermaksan’s advanced laser technology, countersunk holes can now be created directly during the cutting process, without the need for additional drilling or milling steps.

Read more PlayINTERNET OF THINGS - SENDING E-MAIL

Machine status and information can be sent to the provided e-mail addresses by connecting the system to the internet. When the machine gives an error, the error code is sent via e-mail.

AUTO SHEET / AUTO MULTISHEET

It allows the part to be cut to be sent to the cutting by selecting the sheet detected by the camera. (Auto Sheet)

Read more PlayAUTOMATIC BEAM CENTERING AND NOZZLE QUALITY DETERMINATION

The camera-aided laser beam centering adjustment system enables the operators to adjust the laser center effortlessly when needed.

Read moreAUTOMATIC NOZZLE CHANGER

Different types of nozzles with different diameters must be used before cutting materials of different types and thickness.

Read more PlayAUTOMATIC PROFILE ALIGNMENT

An automatic profile alignment system has been developed for precise profile cutting with a profile cutting table in machines with Fibermak pipe and profile cutting options.

Read more PlayAUTOMATIC NESTING

It is the process of relocating the part with data on the image taken from the camera and decoding it.

PIERCETEC CUT CONDITION

With its integrated sensor, PierceTec controls laser power and drilling duration in real time. s.

Read more PlayBECKHOFF CONTROLLER

With its proven industrial PC-based control technology, Beckhoff offers a wide range of products for different applications.

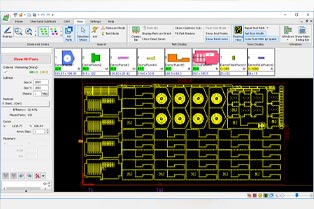

Read moreMETALIX CAD/CAM SOFTWARE

Offering a complete and comprehensive CAD/CAM solution, Metalix updates its software based on the latest developments in sheet metal processing technologies.

Read moreLANTEK EXPERT CUT CAD/CAM SOFTWARE

Lantek Expert Cut is a nesting software designed for users to simply follow the steps specified by the system.

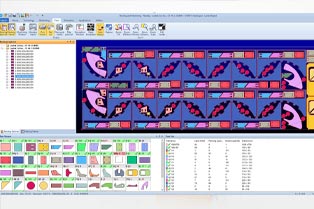

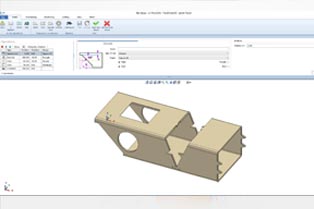

Read moreLANTEK FLEX3D CUT CAD/CAM SOFTWARE

It facilitates 3D CAD/CAM design and cutting of standard profiles, including square or round pipes.

Read moreLANTEK FLEX3D TUBE CUTTING SOFTWARE

Lantek Flex3d Tubes is a CAD/CAM software system for designing, nesting and cutting pipes and pipe pieces.

Read moreERMAKSAN RESONATOR

State-of-the-art fibre laser resonators produced in Ermaksan Optoelectronics centre stand out with their power classes ranging from 1 to 15 kW, high beam quality, and advanced control features.

Read moreIPG-YLR SERIES RESONATOR

Being customized according to customer needs and requests, IPG-YLR Series (Cassette type) resonators offer affordable solutions to their users. Power alternatives between 1 to 4 kW are available.

IPG-YLS SERIES RESONATOR

IPG-YLS Series (Cabin type) resonators, which are provided according to customer needs and requests, have significant advantages thanks to the quality of easy and on-site maintenance. Power options from 1 to 20 kW are available.

MAXPHOTONICS ELITE SERIES

Maxphotonics ELITE-Series is a laser source that balances cost and performance effectively.

Read moreMAXPHOTONICS PRO SERIES

Maxphotonics PRO-Series stands as the flagship of the Max family's CW lasers, integrating the most advanced technology and laser cutting expertise.

Read moreIPG COOLING UNIT

In high-performance industrial laser cutting systems, maintaining optimal thermal balance is essential for operational continuity and cutting accuracy.

Read morePRECITEC LIGHTCUTTER AUTO FOCUS CUTTING HEAD

LightCutter is an ideal and economical solution for all laser cutting applications in the low to medium power range up to 4 kW.

PRECITEC PROCUTTER 2.0 CUTTING HEAD

With the ProCutter 2.0 cutting head, you will no longer need to choose between high quality and high speed, because you can obtain both.

Read moreFIBERTUBE CONVEYOR

The processed pieces are transported to one side with the automatic unloading system, while the scraps are transferred to a separate compartment with the conveyor.

CLEAN - DRY AIR SYSTEM

This system ensures that the oil and moisture levels are reduced to certain figures in order for the values of air coming out of the compressor are at desired levels before the air is transferred to the machine.

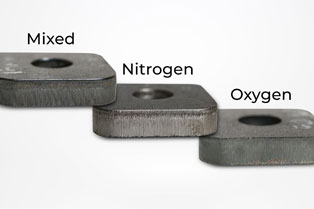

Read morePROPORTIONAL VALVE SYSTEM

This is the system that automatically adjusts the O2 or N2 auxiliary gas according to the material type, and the auxiliary gas pressure according to the material thickness, and transfers the gas to the cutting head.

FILTERING UNIT

Ensures cleaning of smoke and small particles formed during cutting via suction.

Read moreEXHAUST FAN

The suction fan sucks the smoke and particles inside and discharges them to another area. Thus, the harmful particles in the air within the working environment are removed.

SAFETY LIGHT BARRIER

Offers a safer working environment with its light protection curtain that is in compliance with CE standards.

FIBER PROTECTION GOGGLES

This is a safety equipment used to prevent harmful beams that occur during cutting.

CENTRAL LUBRICATING SYSTEM

Automatic central lubrication for extended machine life and minimal maintenance.

Read more

SMART FACTORY SOLUTION PARTNER

It supports you in reaching your production targets in your smart factory thanks to the Industry 4.0 software we have developed in harmony with the digital transformation era.

UNINTERRUPTED CONTINUOUS CUTTING PROCESSES

Thanks to the loading unit developed for the machine to work without interruption and fully automatically, the pipes-profiles can be loaded in bulk.

HIGH DYNAMIC CONTROL

Motors with high dynamic control are used to make mirror movements fast and positioning extremely precise.

SERVO MOTOR TECHNOLOGY

Energy saving, minimum noise, precise positioning, high quality and speed pipe-profile processing is possible thanks to the servo motor technology.

CUTTING IN DIFFERENT GEOMETRIC SHAPES

Square, rectangular and pipe profiles can be cut, plus, loading and cutting is possible in a wide range of material types and thickness.

RIGID CONSTRUCTION

Thanks to its tension- and stress-relieved body, the machine is capable of operating without any problems under harsh conditions for many years.

Similar Products

Check out the other products in the category!

FIBERTUBE - ECO

The FIBERTUBE - ECO is an affordable, versatile tube laser cutting machine that offers precise processing for various tube and profile types with both semi-automatic and manual options.

View product