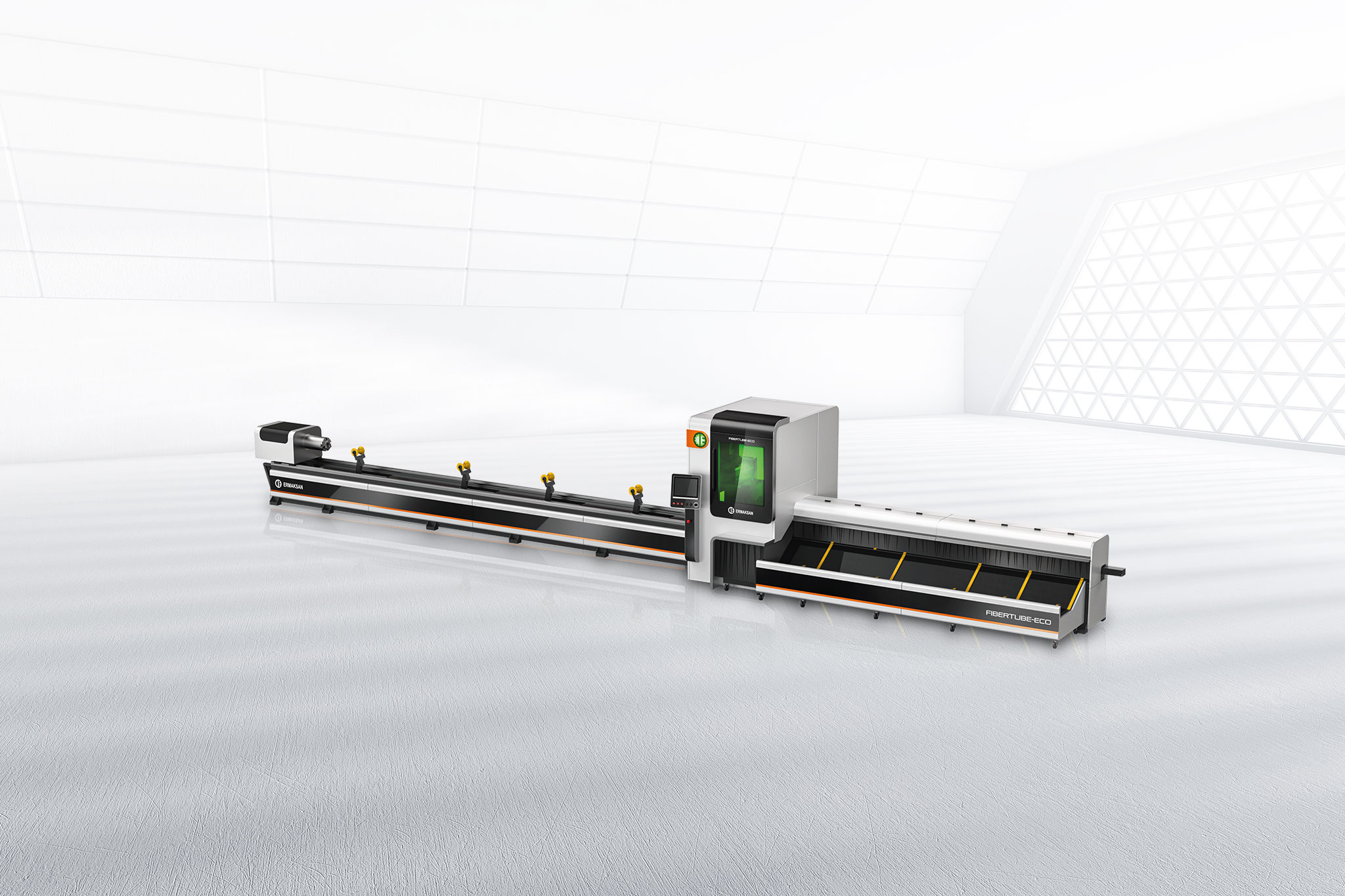

FIBERTUBE - ECO

FIBERTUBE – ECO TUBE & PROFILE LASER CUTTING MACHINE

Affordable Solutions for Pipe and Profile Processing

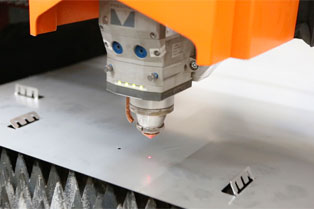

The FIBERTUBE - ECO is a versatile tube and profile fiber laser cutting machine designed for efficiency and flexibility. It offers both semi-automatic and manual operation options, providing users with options to suit their specific needs and preferences.

This machine boasts exceptional processing capabilities, capable of handling round, square, and rectangular tubes with diameters up to 200x6500mm. Its cutting specifications cover a wide range, accommodating round tubes from 20 to 200mm in diameter, square tubes from 20x20 to 140x140mm, and rectangular tubes from 20x30 to 100x150mm.

With a compact design, the FIBERTUBE - ECO features machine dimensions of 14600x5000x2600mm and a machine weight of 8500kg. Despite its smaller footprint, it delivers reliable performance with 0.5G acceleration and 10 axes for precise control and maneuverability.

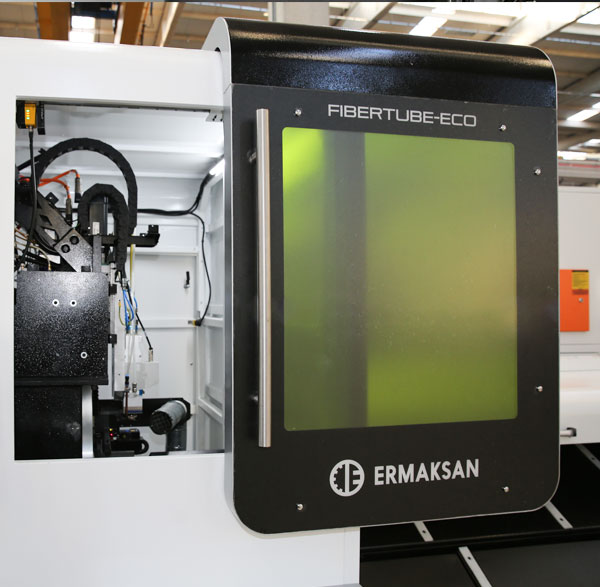

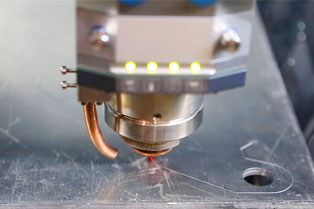

This machine is equipped with high-quality components, including BECKHOFF CNC and servo motors, as well as a Precitec LightCutter Autofocus cutting head, ensuring accurate and efficient cutting operations. It also offers compatibility with leading CAD/CAM software options such as Lantek or Metalix (MTube), enabling seamless integration and optimized cutting paths.

The FIBERTUBE - ECO is designed to handle tubes and profiles weighing up to 960kg, with a loading length of 6000mm and a maximum unloading length of 4500mm. Its versatility and reliability make it an ideal choice for various manufacturing environments, providing efficient and precise cutting for a wide range of tube and profile processing applications.

FLY-CUT FEATURE

With the Fly-Cut feature, you can cut both circular and equilateral pieces at great speeds with great quality.

PlayFREQUENCY CUTTING MODE

Thick material piercings are performed more quickly and heating of the material cut is prevented.

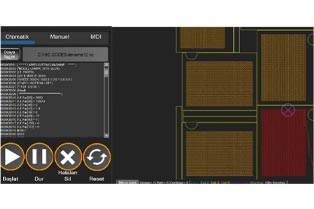

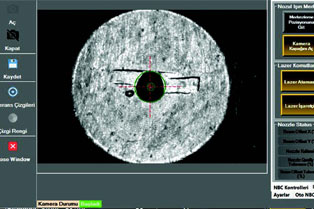

Read moreNC GRAPHICS AND REALTIME STREAMING

While the machine is cutting, it displays the 2D graphic of the NC code in color and allows you to follow which line of code it is on, all within a simple and user-friendly interface.

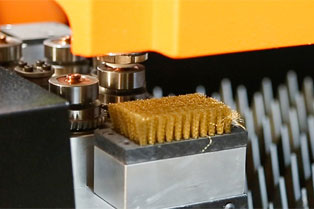

NOZZLE CLEANING / CALIBRATION

It is the process of autımatically cleaning the slag and dirt accumulated in the nozzle used with the nozzle cleaning system, offered in standard with Fibermak series lasers, by means of a cleaning brush.

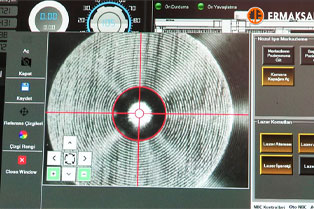

PlayBEAM CENTERING CAMERA

The camera-aided laser beam centering adjustment system enables the operators to adjust the laser center effortlessly when needed.

Read more PlayANTI CRASH SYSTEM

During cutting, possible collision between the laser cutting head and the displaced pieces is prevented, protecting the cutting head against damages.

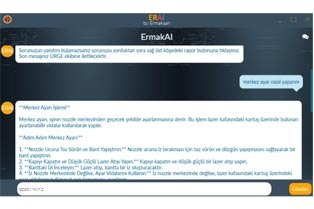

Read more PlayERAI - AI ASSISTANT

With ERAI - AI Assistant, discover features you didn't know about your machine, access solutions to errors, aand have a guide to show you the way.

Read moreCOUNTERSINK BY LASER

Thanks to Ermaksan’s advanced laser technology, countersunk holes can now be created directly during the cutting process, without the need for additional drilling or milling steps.

Read more PlayINTERNET OF THINGS - SENDING E-MAIL

Machine status and information can be sent to the provided e-mail addresses by connecting the system to the internet. When the machine gives an error, the error code is sent via e-mail.

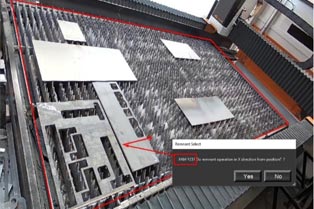

AUTO SHEET / AUTO MULTISHEET

It allows the part to be cut to be sent to the cutting by selecting the sheet detected by the camera. (Auto Sheet)

Read more PlayAUTOMATIC BEAM CENTERING AND NOZZLE QUALITY DETERMINATION

The camera-aided laser beam centering adjustment system enables the operators to adjust the laser center effortlessly when needed.

Read moreAUTOMATIC NOZZLE CHANGER

Different types of nozzles with different diameters must be used before cutting materials of different types and thickness.

Read more PlayAUTOMATIC PROFILE ALIGNMENT

An automatic profile alignment system has been developed for precise profile cutting with a profile cutting table in machines with Fibermak pipe and profile cutting options.

Read more PlayAUTOMATIC NESTING

It is the process of relocating the part with data on the image taken from the camera and decoding it.

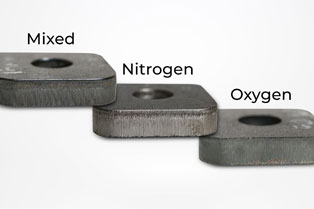

PIERCETEC CUT CONDITION

With its integrated sensor, PierceTec controls laser power and drilling duration in real time. s.

Read more PlayVERSATILE OPTIONS

The FIBERTUBE - ECO provides the flexibility of both semi-automatic and manual operation, allowing customers to select the option that best fits their preferences and operational requirements for optimal efficiency.

BROAD CUTTING CAPABILITIES

Capable of processing round, square, and rectangular tubes with diameters up to 200x6500mm, it handles diverse cutting requirements with precision.

COMPACT YET POWERFUL

With dimensions of 14600x5000x2600mm and a weight of 8500kg, this machine offers robust performance within a compact footprint, featuring 0.5G acceleration and 10 axes.

HIGH-QUALITY COMPONENTS

Equipped with BECKHOFF CNC, servo motors, and a Precitec LightCutter Autofocus cutting head, ensuring accurate and efficient cutting operations.

SOFTWARE COMPATIBILITY

Seamlessly integrates with leading CAD/CAM software like Lantek or Metalix (MTube) for optimized cutting paths and enhanced operational efficiency.

HEAVY-DUTY HANDLING

Designed to process tubes and profiles up to 960kg, with a loading length of 6000mm and unloading length of 4500mm, offering versatility and reliability for various manufacturing needs.

Similar Products

Check out the other products in the category!