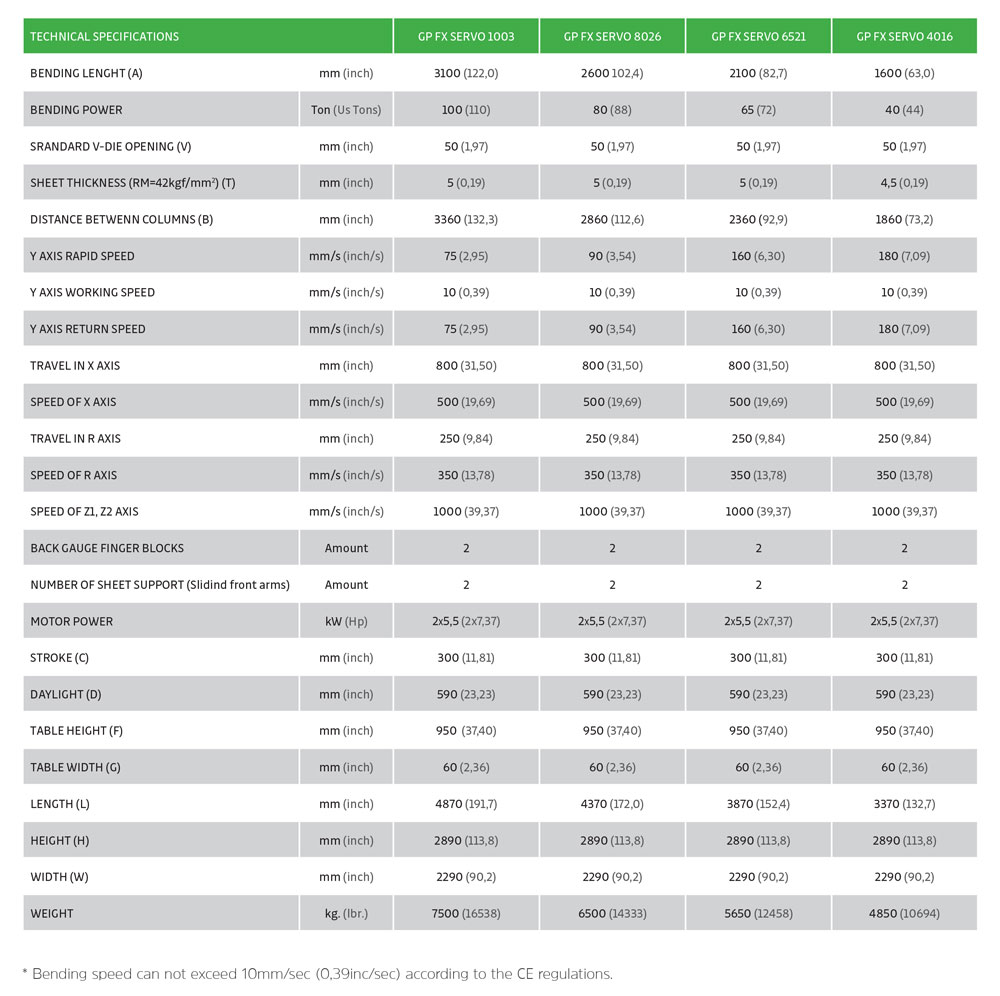

GREEN PRESS FX SERVO

GREEN PRESS FX - SERVO MOTOR ELECTRIC PRESS BRAKE

Quiet, Clean and Energy-Efficient Bending Solution

Green Press FX is one of Ermaksan’s signature eco-friendly innovations, delivering high-efficiency performance with quiet operation and ultra-low energy consumption. Compared to traditional hydraulic press brakes, it consumes approximately 69% less energy — making it an ideal choice for sustainable manufacturing.

Operating without hydraulic oil, the machine eliminates the need for filters, seals, or other hydraulic system components, significantly reducing maintenance costs. It also prevents environmental hazards such as oil leakage, contributing to a cleaner and safer workplace.

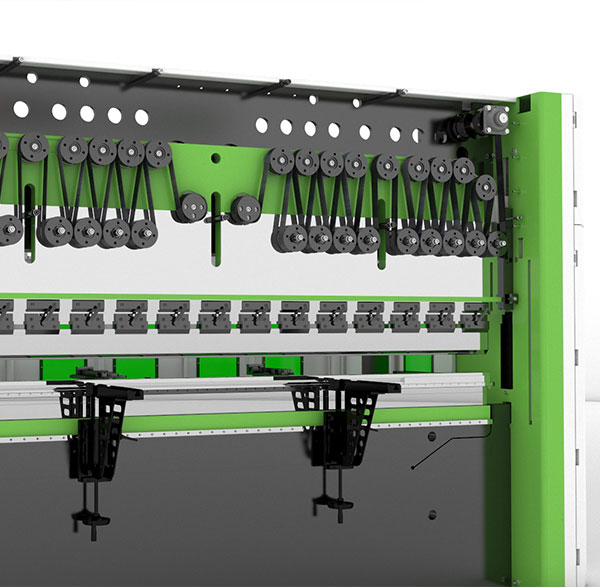

The precision carriage and front sliding support arms, which move laterally along the rail, allow the operator to easily control sheet metal from the front. Measuring rulers mounted on the support arms enable precise length measurements, while the latch embedded in the T-channel helps secure the sheet firmly during bending.

Green Press FX offers a smarter way to bend — combining clean technology with operational excellence.

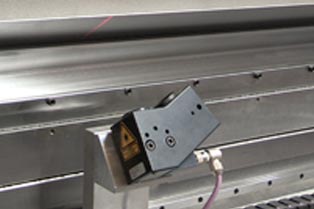

DATA-M LASER PROTRACTOR

Developed by Data M Engineering, it is a powerful solution for measuring bending angles in press brakes.

Read more PlayIRIS PLUS LASER PROTRACTOR

Automatic angle measurement and automatic correction of bending angle

Read more PlayKEBA DIGITAL ANGLE GAUGE

With KEBA angle measuring systems, complex bends can be performed extremely easily and with maximum accuracy.

Read moreMITUTOYO UNIVERSAL ANGLE GAUGE

Can make your measurements more accurately with its sensitive adjustment.

Read moreBARCODE READER

Facilitates the operator's intensive and complex work processes and prevents errors.

Read moreLED BAR GUIDING SYSTEM

Shows the location of the bent pieces and bending stations with coloured LED bars.

PlaySTART-STOP

This is the optional system that stops the main motor when there is no upper beam movement in the machine within 2 minutes.

START-STOP + SOFT STARTER

This is the STAR - TRIANGLE motor speed change that we use as an option. Ensures safer and easier speed change for the motor.

4-AXIS BACKGAUGE

Backgauge with 4-axis (X, R, Z1, Z2) servo motor allows you to obtain precise bending of the backgauge with 0.05 mm positioning accuracy according to the desired geometry.

5-AXIS BACKGAUGE

Backgauge with 5-axis (X, R, Z1, Z2, X5) servo motor allows you to obtain precise bending of the backgauge with 0.05 mm positioning accuracy according to the desired geometry.

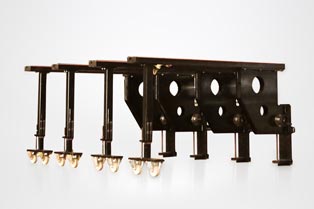

Read more PlayATF TYPE 6-AXIS BACKGAUGE SYSTEM

Ermaksan’s ATF Type Backgauge System is engineered for manufacturers who demand exceptional accuracy and efficiency in complex and multi-step bending operations.

Read more PlayPNEUMATIC REAR SUPPORTS

The Pneumatic Rear Supports are additional support latches mounted to the machine to facilitate easier and more accurate bending operations.

Read moreX5 BACKGAUGE FINGER GROUP

The X5 Backgauge Finger Group is equipped with 5 servo motors, providing exceptional positioning accuracy of 0.05 mm based on the geometry of the part.

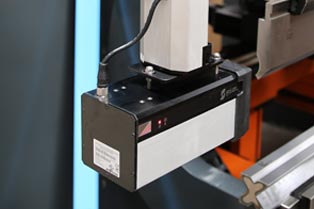

Read moreLEUZE MLC510 – REAR SAFETY LIGHT CURTAIN

The LEUZE MLC510 rear safety light barrier provides advanced protection by automatically stopping the machine when any object enters the rear working area during operation.

Read moreREARGUARD+SWITCH

Ensure maximum operator safety with the integrated rear sliding guard and safety switch system.

Read moreMOTORIZED REAR SHUTTER DOOR

A motorized or manually operated rear safety door designed with durable aluminum slats.

Read more PlayDOUBLE FOOT PEDAL

A user-friendly dual foot pedal designed to offer precise and hands-free bending control.

Read moreCOBOT-INTEGRATED BENDING SYSTEMS

Ermaksan’s cobot-integrated press brakes make sheet bending processes safe, precise, and efficient, delivering a next-generation automation experience in manufacturing.

Read more PlayFULLY AUTOMATED ROBOTIC BENDING SYSTEMS

Ermaksan’s integrated robotic press brake systems fully automate sheet metal bending, delivering maximum efficiency, precision, and consistency on production lines.

Read more PlayLASER BEND LINE - B-LIGHT 02

A laser-guided alignment system fixed to the upper beam to indicate the bending axis.

Read moreLASER BENDING LINE - ROLLERI B-LIGHT 01

A laser alignment tool that mounts easily to the promecam system to indicate the bend line.

Read moreRULER ON TOP BEAM

You can get precise results with Y1+Y2 axis synchronization with a tolerance of 0.01 provided by linear rulers.

DELEM DA-66T

The 2D touchscreen display controller is your best assistant in the most difficult bending operations with its functional features.

Read moreDELEM DA - 66S

24” touchscreen, 2D programming with auto bend sequencing & collision detection, plus full 3D setup—for higher accuracy, faster setup, and seamless integration.

Read moreDELEM DA - 69S

Delem’s flagship 24” touchscreen press brake control—delivers intuitive 2D/3D programming with automatic bend sequencing and collision detection, full 3D machine setup and simulation, seamless integration, and offline Profile-S3D support.

Read moreDELEM DA-69T

DA-Touch series, 3D graphic display controller is always by your side to ensure the most precise bending operations with its powerful features.

Read moreER 99 PLUS

Meet Step Automation's new-generation ER 99 series customized for Ermaksan users, an Italy design that delivers greater efficiency in press brake programming and control.

Read moreSTANDARD CONTROLLER ARM

The standard component that allows the CNC controller to be positioned at the front or rear of the machine when needed.

Read moreERGONOMIC CONTROLLER ARM

Ergonomically designed arm allowing smooth forward-backward and side-to-side movement for operator convenience.

Read moreHEIGHT ADJUSTABLE CNC PENDANT ARM

Ideal for multi-operator use, this arm allows frequent height adjustments of the controller with ease.

Read moreL TYPE SLIDING FRONT SUPPORT ARM

Sliding front support arms with stopper, metric system scales and height adjustment feature allows more precise and easier bending operations.

PlayAP3-AP4 FRONT SUPPORT ARMS SYSTEM

Advanced support solution for precise and safe sheet metal bending

Read moreWIDE TYPE FRONT SLIDING ARM

They are optional foot type front arms used in machines with high sheet width and special bending.

U TYPE SLIDING FRONT SUPPORT ARM

It is the front arm body of all our machines (except Eco-Bend Expert), which is created using a light curtain and used for front security.

SIDE CAGE+SWITCH+LEUZE

If the brackets used as front light protection detect an object in the beam movement, they stop the movement of the beam; if the beam is removed, the beam keeps moving at the same speed. However; if the object remains in between, the beam keeps moving at a low (manual) speed.

SIDE CAGE+SWITCH+AKASII

AKAS finger protection stops the movement of the upper beam when an object is detected.

Read moreSIDE CAGE+SWITCH+AKASII

AKAS finger protection stops the movement of the upper beam when an object is detected.

Read moreSIDE CAGE+SWITCH+DSP AP MCS

DSP MCS AP stops the movement of the upper beam when an object is detected. The beam continues to move if the object is removed.

SIDE CAGE+SWITCH+LASERSAFE IRIS

The system, which is also used as a front finger protection, stops the movement of the upper beam when an object is detected.

Read moreSIDE CAGE+SWITCH+LASERSAFE IRIS PLUS

This is a system that can measure the angle and automatically make angle correction to the CNC.

Read moreSIDE CAGE+SWITCH+LASERSAFE

The system, which is also used as front finger protection, stops the movement of the upper jaw when it detects any object.

Read more

QUIET OPERATION

The beam’s downwards and return movements are ensured by means of springs. Thus, the machine works silently and does not create any noise pollution that may disturb the environment.

LOW MAINTENANCE COST

Hydraulic system and cylinders are not used in the machine. Since it is a completely mechanical machine, you can use it with less maintenance cost.

ENVIRONMENTALLY FRIENDLY

Since a servo motor with high energy efficiency is used in the machine, which does not require industrial oil, it is an environmentally friendly machine, standing out with its high power and low energy consumption.

UNLIMITED FULL LENGTH BENDING

Contrary to the known press brake, this machine does not have a throat. Performs full-length bends between the feet. It has no restrictions according to the hydraulic press.

LOW ENERGY CONSUMPTION

An energy efficient servo motor is used. Motors do not operate when the upper beam is not moving. It provides an energy saving of 69%.

RIGID CONSTRUCTION

It has a strong body with dynamic and static rigidity processed with high precision.

Similar Products

Check out the other products in the category!

EVO-III

Electro-hydraulic press brakes that offer the ideal solution for low-cost operations without sacrificing from bending quality.

View productSPEED-BEND PRO

It is designed to reduce your unit time costs with its fast and precise production capability.

View productBSCRW

Experience the BSCRW Series Ball Screw Servo Electric Press Brake, an advanced machine engineered to set new standards in productivity, precision, and sustainability.

View productPOWER-BEND FALCON

Power-Bend Falcon Series machines redesigned based on users preferences to become a unique machine with its individual electronic and mechanical features.

View productPOWER-BEND PRO

It is designed to maximize your bending performance in different material types.

View productMICRO BEND

If you do not have much space, the most efficient and smallest hydraulic press brake of its class is by your side.

View productECO-BEND EXPERT

Its hardware that does not compromise on quality offers low-investment solutions for your business.

View productHEAVY DUTY

We offer the most ideal solution for your needs with our high tonnage and customized press brake production experience and R&D power.

View product