LASER AUTOMATION SOLUTIONS

Laser Automation Solutions

Sheet Metal Loading & Unloading Systems

Maximize your productivity and elevate your operations with ERMAKSAN’s state-of-the-art laser automation solutions. Engineered to meet the diverse demands of high-volume and precision sheet metal processing, our advanced loading and unloading systems provide fast, safe, and error-free material handling. By fully automating sheet transfer operations, these solutions minimize downtime, reduce operator workload, and significantly enhance overall production efficiency, giving your business a real competitive edge.

To further maximize your efficiency and profitability, ERMAKSAN’s professional team is ready to help you determine the ideal combination of machines, towers, conveyors, and loading systems. Discover the most suitable laser automation solutions for your business today.

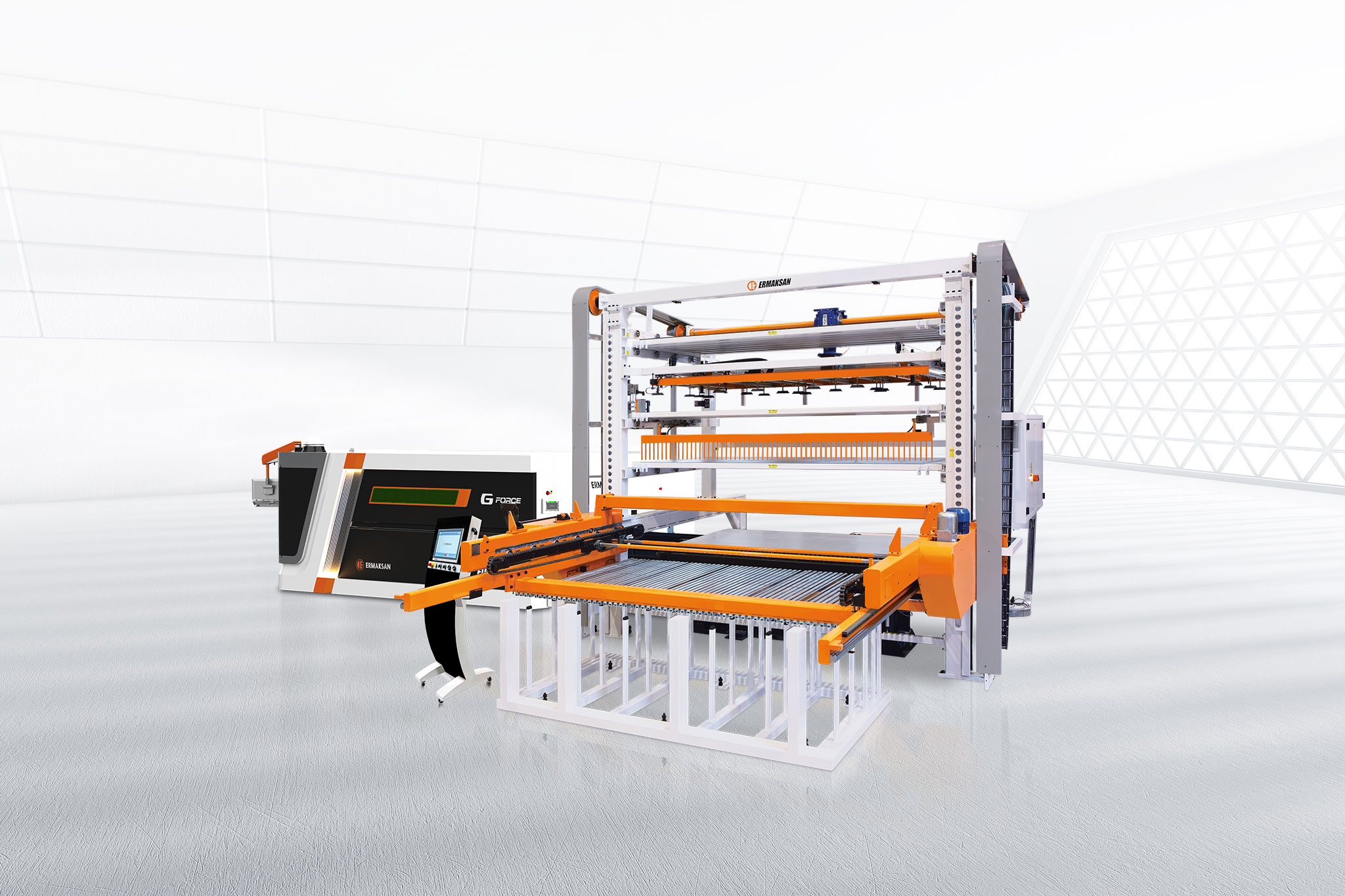

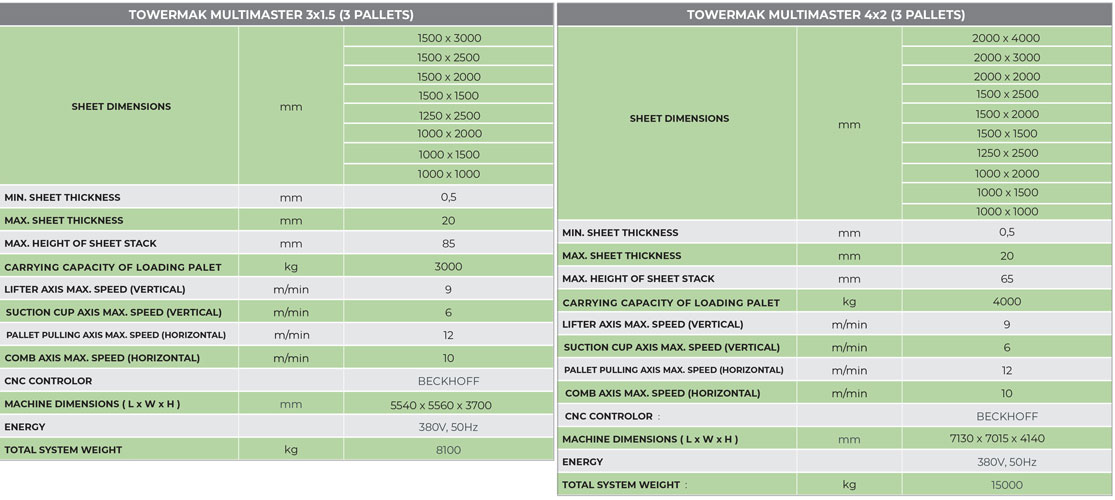

TOWERMAK – Tower Type Loading & Unloading System

TOWERMAK is designed for unmanned loading and unloading of 1500x3000 mm sheet metals for laser cutting machines. It offers high reliability, flexibility, and ease of use, increasing production capacity by over 60% depending on material type, thickness, and nesting. With its multi-pallet stacking system, it prevents space loss in workshops while protecting sensitive sheets against scratches and impacts.

Read moreTOWERMAK DOUBLEMASTER – Multi-Laser Integration

The TOWERMAK DOUBLEMASTER Series offers seamless integration with two or more laser cutting machines, providing lights-out production with minimal human intervention. Featuring smart manufacturing software, it enables real-time monitoring, optimized workflow, and significant labor cost reduction, boosting overall productivity for large-scale operations.

Read moreERMAUTOMATION – Robotic Automation Line

The ERMAUTOMATION Robotic Automation Line fully automates laser cutting and bending processes, eliminating downtime caused by manual handling. Featuring fiber laser with tower automation and robot-equipped press brakes, it delivers a flexible, high-efficiency production line. This integrated system significantly increases productivity, optimizes workflows, and reduces operating costs.

Read more

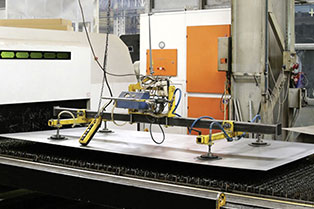

Bridge Type Vacuum Loading System

The Bridge Type Vacuum Loading System automates raw material loading onto the shuttle table with perfect alignment, making it ideal for high-volume production. It reduces manual handling, cuts labor costs, improves workplace safety, and ensures continuous, high-speed operations.

Read more

LoadMaster Vacuum Loading System

The LoadMaster combines automation and precision with its jib crane-based design, enabling fast, accurate sheet loading directly onto the shuttle table. Designed for high-volume manufacturers, it reduces material handling time and improves overall machine efficiency.

Read more

VacuMaster Vacuum Loading System

The VacuMaster offers semi-automatic operation, providing an affordable and user-friendly solution for businesses seeking efficient sheet loading without full automation. It ensures safe and precise material handling, improving cutting consistency and operator safety.

Read more

RoboMaster Vacuum Loading System

The RoboMaster integrates ERMAKSAN’s Fibermak laser cutting machine with advanced robotics to perform automatic sheet loading, unloading, and stacking. This all-in-one solution maximizes machine performance, minimizes human intervention, and delivers 24/7 Industry 4.0-ready production.

Read more

FULLY AUTOMATED SYSTEM

The system can operate in a full-automatic manner by automatically loading the appropriate sheet metal and suitable cutting parameters for each material. Therefore, you can perform mass production and minimize time losses.

MASS PRODUCTION

By minimizing the operator-induced errors, a high-quality production process is carried out much faster.

FLEXIBILITY

It is designed with a flexible production focus for users who want to process different types of materials easily and without burrs.

FACTORY AUTOMATION

Fibermak laser cutting machine, which works in full harmony with tower loading and unloading systems, increases production quality and productivity, and provides your business with a competitive advantage.

EASE OF USE

In addition to efficient and fast operation, there are simple language options and easy programming to facilitate the operator's work. With this structure, it offers easy and reliable production management.

OPPORTUNITY TO INTEGRATE WITH FIBERMAK

It is possible to integrate the most suitable TOWERMAK loading and unloading system into existing FIBERMAK laser cutting machines for our customers who would like to automate their laser cutting processes.

Similar Products

Check out the other products in the category!

FIBERMAK MOMENTUM GEN-5

A next generation Fibermak that provides its users with superior performance at high cutting speeds.

View productFIBERMAK MOMENTUM GEN-3

Superior Ermaksan technology, which has won many international awards with its strong and dynamic design; for those who know what they want.

View productFIBERMAK RAPTOR

Developed with modular and ergonomic design in mind, Fibermak Raptor offers an economical solution without sacrificing from cutting quality.

View productHAWK LASER

Thanks to its easy-to-install and compact structure, it provides a fast and efficient production laser process by reducing the installation, assembly, commissioning, and transportation times.

View productTHUNDERBIRD

The new THUNDERBIRD fiber laser machine offers an easy entry to the world of fiber laser cutting with its compact structure that does not require costly equipment.

View productTHUNDERBIRD COMPETITION

The THUNDERBIRD COMPETITION is the newest member of our laser cutting machine family, developed to meet the needs of today’s highly competitive market.

View productROBIN

The ROBIN Laser Cutting Machine is engineered as an accessible yet highly reliable solution for businesses seeking efficient laser cutting with minimal investment.

View productFIBER LASER SPECIAL MACHINES

In addition to our standard product portfolio we have offered to the world of laser cutting, we are by your side throughout the entire process with our flexible solutions tailored to different needs.

View product