SPEED-BEND PRO

STANDARD BACKGAUGE REST AXES

It provides both time and cost savings thanks to its ability to perform complex bending easily with its standard 4-axis back rest (X, R, Z1, Z2) and other accessories that assist bending.

PRECISION BENDING

Thanks to the standard motorized crowning system, the deflection balance can be ideally achieved with the motor. Thus, precise bends are obtained.

LOW OPERATING COST

Provides minimal energy consumption. Cylinders and hydraulic installations that provide easy maintenance are used. Thus, maintenance needs are kept at minimum. This way, the machine offers low operating costs.

QUICK PAY OFF

With its speed and versatility, it is a profitable investment and can pay off for itself in a short time.

PRECISION PROGRAMMING

Fast, easy, error-free, and precise programming is possible thanks to the linear rulers produced at high quality standards in special production facilities.

SLIDING FRONT SUPPORT ARMS

Sliding front support arms with stopper, scaled according to the metric system, allows more precise and easier bending operations.

SUBSCRIBE E-NEWSLETTER

You can subscribe to the e-bulletin to receive information regarding the developments about Ermaksan

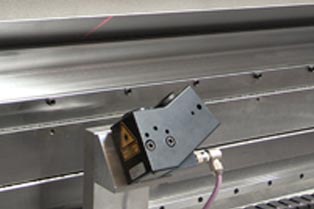

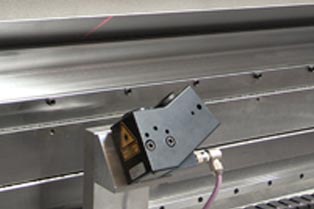

DATA-M LASER PROTRACTOR

DATA-M LAZERLİ AÇIÖLÇER

This is the semi-automatic laser-based bending angle measuring device enables the user to determine the exact bending angle for press brakes by a built-in semiconductor laser with line optics and the 1/3” CMOS-camera together with strain gauges – and it works contactlessly.

The bending angle is measured by scanning the projection of the laser beam to the surface of the sheet metal with the CMOS camera. The angle between the laser and the viewing axis of the camera defines the correlation between the position of the line in the camera image and the angle between the sensor and the sheet metal. With a second sensor at the opposite site the bending angle is calculated.

It is mounted on the press brake under an angle of 45° to the die in a working distance of 160-300 mm below the die. It is moveable along the die manually (or automatically). Due to its mounting position the measuring range is 0° to 180°. For each measuring position there are 2 sensors needed.

The sensor accuracy is better than ±0.1°. The system accuracy is influenced by the control, the machine accuracy, the tools and the material. To increase the bending accuracy the sensors were calibrated after mounting. So, the mounting errors are reduced.

The result is a bending angle with a never seen precision just after one bending step regardless of if differences in material properties such as thickness or other.

KEBA DIGITAL ANGLE GAUGE

KEBA DIGITAL AÇIÖLÇER

The first advantage of this system is allowing the bending of complex shapes easily and accurately within view, especially Z-bends or narrow parts. Complete quality control is possible with this system without any additional time and with maximum accuracy and reproducibility.

KEBA KeMes A200 device procures to see the angles that it measures, on your controller’s screen while communicating with it’s smart Bluetooth USB dongle. It is located on punch easily by the help of the magnets which are inside of it. Device calculates the current angle while bending under favor of lasers which are spreads on a single source. KeMes A200 is easy to use and it has 2 mods which names are “Machine” and “Manual” can make optionally single measurement, continuous measurement and automatic measurement which is called “Machine” mod. The aim of machine mod is analyzing upper beam movements. It can be charged with USB cable and its adapter and its battery life is about 6 hours.

ErTouch controller instantly shows data that is received from sheet with the aid of KEBA integration. After bending is over, ErTouch offers chance to enter correction angles by comparing the angle measured by KeMes A200 and the angle programmed by user. This devices measurement range is between 30° and 150° and its measurement precision is ±0.2°. It has 162 mm width, 48.5 mm height, 15.3 mm depth and measurement results is shown on its high-contrast OLED display.

5-AXIS BACKGAUGE

5 EKSEN ARKA DAYAMA

One of the backgauge latches moves within ±100 mm and enables conical bending.

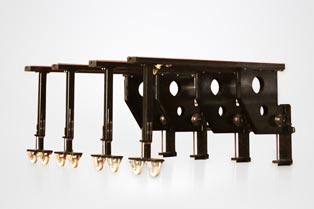

ATF TYPE 6-AXIS BACKGAUGE SYSTEM

6 EKSEN ARKA DAYAMA ATF TİPİ

Precision. Flexibility. Automation.

Ermaksan’s ATF Type Backgauge System is engineered for manufacturers who demand exceptional accuracy and efficiency in complex and multi-step bending operations. Equipped with 6 high-speed servo-controlled axes (X1, X2, R1, R2, Z1, Z2), the system enables:

✅ Precise and fully automatic part positioning, even for asymmetrical or multi-angle parts

✅ Faster setup times, reducing downtime between production batches

✅ Enhanced repeatability and accuracy, critical for high-volume and high-precision bending tasks

✅ Dynamic adaptability to complex geometries, offsets, and irregular part shapes

✅ Improved operator safety and reduced manual adjustments

Designed to work seamlessly with Ermaksan’s advanced press brake models, the ATF backgauge system maximizes throughput and reduces error margins—making it an ideal solution for industries such as aerospace, automotive, defense, and contract metal fabrication.

Technical Highlights

Axes Configuration: X1, X2, R1, R2, Z1, Z2 (independent movement for full flexibility)

Servo Motor Control: High-speed, high-accuracy movement on all axes

CNC Integration: Full compatibility with Delem, ESA, and Cybelec controllers

Robust Construction: Rigid frame and anti-vibration design for consistent performance

Software Support: Offline programming and 3D simulation-ready

Ideal For

Complex parts requiring multi-bend sequences

Variable-size production with frequent part changes

Precision applications where repeatability is critical

Factories aiming to scale with automation and smart manufacturing systems

LEUZE MLC510 – REAR SAFETY LIGHT CURTAIN

LEUZE MLC510 ARKA KORUMA

The LEUZE MLC510 rear light curtain provides Category 4 level safety protection in accordance with IEC 61496 standards. The system continuously monitors the rear working zone using infrared transmitter-receiver pairs and interrupts machine operation upon any detected intrusion.

This ensures operator safety without physical barriers and is ideal for high-throughput environments requiring frequent rear-side access for material handling or process observation.

REARGUARD+SWITCH

ARKA KAPALI KAFES+SWITCH

The REARGUARD+SWITCH is a manually operated rear sliding guard system equipped with an integrated safety interlock switch. Its steel-framed structure includes observation windows made of impact-resistant transparent panels, allowing visual monitoring of the internal machine area without removing the guard.

When opened, the interlock switch sends a stop signal to the safety PLC, disabling machine motion and ensuring compliance with EN ISO 14120 and EN ISO 13849-1 safety standards.

MOTORIZED REAR SHUTTER DOOR

PANJUR TİPİ MOTORLU ARKA KORUMA

This motorized rear protection shutter is constructed from interlocking aluminium slats and can be controlled either electrically or manually, depending on configuration. Available in anthracite grey or metallic grey color options, it provides both safety and aesthetic value.

The system includes integrated sensors that communicate with the safety PLC to stop the machine when the shutter is open, ensuring compliance with safety regulations and ease of use in automation environments.

DOUBLE FOOT PEDAL

ÇİFT AYAK PEDALI

Ergonomically designed dual foot control pedal enables hands-free and precise control of the bending process. The dual configuration allows flexible operation for both simple and complex bending cycles, enhancing operator safety and comfort.

MOTORISED CROWNING SYSTEM

MOTORLU BOMBELEME

In bending operations, natural deflection in the machine frame causes varying bend angles between the center and ends of the workpiece, especially in long parts. The CNC-controlled motorised crowning system eliminates this issue, ensuring consistent and accurate bend angles across the entire length of the workpiece.

Fully integrated with the CNC controller, the system automatically adjusts crowning during bending. This delivers high precision and repeatability without the need for manual intervention.

Advantages

- Fully Automatic Adjustment: Automatic crowning compensation based on CNC bending parameters.

- Perfect Precision: Consistent and even bend angles along the whole part.

- Time Savings: Eliminates manual adjustment, increasing production speed.

- High Efficiency: Maximum performance in mass production.

- Low Error Rate: Prevents human adjustment errors.

- Quality Assurance: Accurate results in a single pass, minimal scrap.

The CNC-controlled motorised crowning system delivers superior quality, speed, and reliability for applications where precision and production capacity are essential.

Discover it now and take your production quality to the next level.

HYDRO-DYN CROWNING SYSTEM

HİDRODİNAMİK BOMBELEME

Thus, it ensures that every point of the bent part is at an equal bending angle.

HYDRAULIC CROWNING SYSTEM

HİDROLİK BOMBELEME

Thus, it ensures that every point of the bent part is at an equal bending angle.

HYDRO-MECHANICAL RIDGING

HİDRO-MEKANİK BOMBELEME

Thus, it ensures that every point of the bent part is at an equal bending angle.

LASER BENDING LINE - ROLLERI B-LIGHT 01

LAZER BÜKÜM ÇİZGİSİ - ROLLERI B-LIGHT 01

The Rolleri B-LIGHT 01 system offers a visible laser-guided bend line without relying on the backgauge. It’s easily attachable and removable from the promecam system where the upper die is mounted, making it a time-saving and efficient tool for various bending applications.

LASER BEND LINE - B-LIGHT 02

LAZER BÜKÜM ÇİZGİSİ - B-LIGHT 02

The B-LIGHT 02 laser bend line system allows operators to clearly see the bending axis without using the backgauge. It is fixed to the upper beam, offering high-accuracy guidance especially during manual alignment or non-standard part bending operations.

HAWE HYDRAULIC SYSTEM

HAWE HİDROLİK SİSTEM

The HAWE Hydraulic System delivers accurate oil circulation at the correct pressure, ensuring optimal performance for the main rollers, pressing rollers, and feeler adjustment rollers. This advanced system enhances machine efficiency, reliability, and long-term durability, even under intensive operating conditions.

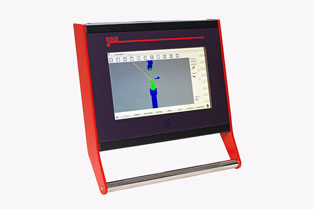

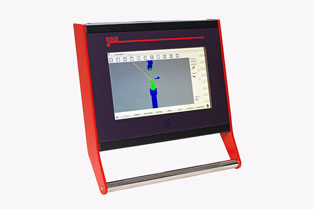

ERTOUCH 15 SMART

ERTOUCH 15 SMART

Standard Specifications

- Maximum 4 Axis

- 2D Display and 2D Programming

- Capacitive Touch Panel

- Windows 10 LTE

- 256 GB Memory

- 2 USB Port

- 2D Display and 2D Programming Offline Software

- Product and Bending Counters

- Number of Products (600)

- Number of Bends (48)

- Number of Material (20)

- Number of Die and Punch (200)

- Hemming and Air Bending

- Quick Help

- FMSC Safety System

- DSP – MCS Safety System

- LazerSafe Safety System

- Remote Access and Diagnostics

- 2 x GigE Ethernet

Optional Specifications

- User Defined System

- Keba Angle Protractor

- Barcode Reader

- 3rd Party Software Support

- User Authorization System

- ER 4.0

- Remote Service System

- Mitutoyo Angle Protractor

CYBELEC CYBTOUCH 15 PS

CYBELEC CYBTOUCH 15 PS

- 15″ modern glass-surface touchscreen operable with gloves

- Intuitive programming interface and dedicated wizards (autotuning) for quick setup

- 2D graphical profile drawing (Touch Profile) and precise 2D program creation

- Automatic bending sequence calculation

- EasyBend page for fast and simple single bends

- Large data storage capacity

- Built-in backup and restore functions

- Wireless communication for remote diagnostics and updates (via laptop connection)

CYBELEC VISITOUCH PAC

CYBELEC VISITOUCH PAC

- 19” modern glass-surface touchscreen operable with gloves

- CNC unit mounted on the back of the screen with interface module inside the cabinet

- Windows 10 operating system with power cut protection and multitasking support

- Open software platform for customization

- Industry 4.0 ready

- 2D graphic profile drawing (Touch Profile) and 3D visualization

- Automatic bending sequence calculation

- User-friendly 2D and numerical programming interface

- Full digital communication via EtherCAT and CANopen

- Supports all kinematics (X, X relatives, X slave, R, R slave, Z axes; back/front multiple gauges; bending aids)

- Tandem operation capability

- Tool import and management

- Group management for complex production

- Preliminary/final bend and hemming management

- Integrated angle measurement

- Barcode reader support

- Modular structure for multi-axis production

CYBELEC VISITOUCH PAC MX

CYBELEC VISITOUCH PAC MX

- 19” modern glass-surface touchscreen operable with gloves

- CNC unit mounted on the back of the screen with interface module in the cabinet

- Windows 10 OS with power cut protection and multitasking support

- Industry 4.0 ready with an open software platform for customization

- Full digital communication via EtherCAT and CANopen

- Programming in 3D, 2D, and numerical modes

- Import of part files in DXF, STEP, and IGES formats

- Full 3D visualization and simulation

- Automatic solutions for complex parts: bend sequencing, gauging, tooling, and auto-segmentation

- Supports all kinematics (X, X relatives, X slave, R, R slave, Z axes; back/front multiple gauges; bending aids)

- Tandem operation capability

- Tool import and management

- Group management for complex production

- Preliminary/final bend and hemming management

- Integrated angle measurement

- Barcode reader support

DELEM DA-66T

DELEM DA-66T

GENERAL SPECIFICATIONS

- 2D graphics touch screen programming mode

- 3D imaging in simulation and production

- 17” high resolution colour TFT screen

- Full-featured Windows application

- Standard Profile-LITE offline software

- 1 GB memory

- Product and tool memory 256 MB

- USB flash memory drive

- Emergency stop button

- Alphanumeric product naming

DELEM DA-69T

DELEM DA-69T

GENERAL SPECIFICATIONS

- 3D and 2D graphics touch screen programming mode

- 3D and 2D imaging in simulation and production

- 17” high resolution colour TFT screen

- Full-featured Windows application

- Profile-T3D offline software

- 1 GB memory

- Product and tool memory 256 MB

- USB flash memory drive

- Emergency stop button

- 2D and 3D automatic bending sequence calculation

- Graphical product and tool selection

- Programmable material properties

- Programmable axis speeds

- Free material programming

- Product and tool search filters

- Millimeters / Inch, kN / Ton selection

- Stroke counter

- Graphic tool configuration

ER 99 PLUS

ER 99 PLUS

- ERMAKSAN CAD/CAM Metal Sheet Bending Simulation

- Ability to Select Automatically Defined Patterns for Bending

- Automatic Twist Sequence Search and Warping Control

- Remote Support via TeamViewer

- Up to 16 Axis Configuration

- Exporting Planar Lines to DXF File

- Scheduled Maintenance Management for Continuous Efficiency

- Ability to Add External Keyboard and Mause

- Alphanumeric Multifunction Keyboard

- Tool and Part Acquisition as CAD File

- Material Sampling for Precision Manufacturing

- Upload Images from Mobile Devices

- Sensor Interface and Display

- Suitable for Industry 4.0

ESA S660W

ESA S660W

- 19” multiple touch screen

- Genuine 3D CAD/CAM image on the machine with integral powerful PC and work piece design with Fingertip

- Direct download of files with *.dxf extension and team library management.

- Top and bottom die holder options

- Up to 12 axes control in any combination

ESA S630

ESA S630

- 10” touch screen with 2D graph

- High-level graphics programming for ease of use

- Up to 4 axes control in any combination

ESA S640

ESA S640

- High performance compact solution with 15” touch screen

- Up to 6 axes control in any combination

- Provides an excellent comfort to the operator with its wide screen by benefiting from the full graphical interface

- Automatic bending sequence calculation and material database registration for preventive compensation to reduce the wastage rate

- Crowning correction with angles

- Up to 6 axes control in any combination

ESA S675

ESA S675

- 21,5” multiple touch screen

- Make the best of any 3D cad cam you would like to install in the CNC.

- Finger-tip work piece design. Direct import of tools shapes (.dxf files)

- and management of tool library.

- Tool and die holders management.

- Angle measurement and correction with all existing devices is available.

STANDARD CONTROLLER ARM

STANDART KONTROLÖR KOLU

The standard pendant arm securely mounts the CNC controller to the machine and allows it to be manually positioned forward or backward when needed. It offers a practical and dependable solution for everyday production needs.

HEIGHT ADJUSTABLE CNC PENDANT ARM

YÜKSEKLİK AYARLI KONTROL KOLU

The height-adjustable pendant arm is designed for workstations shared by multiple operators. It allows easy adjustment of the controller's height, ensuring ergonomic comfort and efficient control for all users.

WILA SMART TOOL LOCATOR

WILA SMART TOOL LOCATOR

The WILA Smart Tool Locator is an advanced positioning system that mounts full-length to the upper beam. Using laser beam technology, it precisely determines the optimal sequence for segmented punches installed in the upper tool holder during bending operations.

System Features

Laser Beam Technology - High-precision laser beam system clearly marks tool positions and provides visual guidance for accurate placement.

Full-Length Mounting - Complete upper beam integration ensures effective positioning capabilities across the entire tool length.

Intelligent Sequence Detection - Automatically calculates and displays the optimal punch arrangement based on specific bending operation requirements.

Seamless Integration - Easy integration with existing upper tool holder systems without modification requirements.

Rapid Setup - Completes complex tool arrangement calculations in seconds, significantly reducing operation time.

The Smart Tool Locator transforms tool positioning from guesswork into a science-based process. With laser guidance, every segmented punch finds its correct position on the first attempt.

Maximize production efficiency with precision tool positioning. Contact us for detailed information about the WILA Smart Tool Locator.

CENTRAL LUBRICATING SYSTEM

MERKEZİ YAĞLAMA SİSTEMİ

The central lubricating system automatically delivers precise lubrication to critical machine components, ensuring longer service life and reduced maintenance needs without requiring operator intervention. Its automatic skid lubrication system further enhances durability by distributing oil from the reservoir to targeted areas via a grease pump, distributor, and hoses at set intervals, keeping the machine in optimal working condition.

AP3-AP4 FRONT SUPPORT ARMS SYSTEM

AP3-AP4 ÖN KOL SİSTEMİ

The AP3-AP4 Front Support Arms System is an intelligent sheet support solution developed to prevent deformation in thin, flexible sheets during bending. It is particularly effective in applications where the skirt (flange) length is large, which can cause the sheet edge to flex downward, resulting in poor part quality and operator difficulty.

By lifting the sheet from below and following the bending path, this system eliminates downward deflection, ensuring that the workpiece maintains its shape throughout the process. The result is more precise, consistent, and operator-friendly bending.

Key Technical Advantages:

- Prevents deformation caused by edge flexing during bending

- Follows the bending path, providing dynamic support from below

- Improves operator ergonomics and increases safety

- Delivers consistent bending quality, even in repetitive operations

- Ideal for large-format parts made of thin or lightweight material

The AP3-AP4 Front Support Arms System is engineered to elevate your bending operations by enhancing precision, repeatability, and operator comfort.

SIDE CAGE+SWITCH+AKASII

YAN KAFES+SWITCH+AKASII (MOTORLU)

If the object is moved out of the way, the jaw continues its movement. Once calibrated, it automatically adjusts the height when the upper mould is changed.

SIDE CAGE+SWITCH+AKASII

YAN KAFES+SWITCH+AKASII (MOTORSUZ)

If the object is moved out of the way, the jaw continues to move. Height adjustment is done manually.

SIDE CAGE+SWITCH+LASERSAFE IRIS

YAN KAFES+SWITCH+LASERSAFE IRIS

If the object is moved out of the way, the jaw movement continues. If the object continues to stand in between, the jaw movement continues at slow speed (manually).

SIDE CAGE+SWITCH+LASERSAFE IRIS PLUS

YAN KAFES+SWITCH+LASERSAFE IRIS PLUS

The system, which can also be used as front finger protection, stops the movement of the upper jaw when it detects any object. If the object is removed, the jaw continues its movement. If the object continues to stand in between, the jaw movement continues at slow speed (manually).

SIDE CAGE+SWITCH+LASERSAFE

YAN KAFES+SWITCH+LAZERSAFE

If the object is moved out of the way, the jaw movement continues. If the object continues to stand in the way, the jaw movement continues at a slow speed (manually).

BARCODE READER

BARKOD OKUYUCU

In order to facilitate work processes and prevent errors, the programme is loaded automatically by reading the code from the sheet or anywhere else. Thus, your production times are reduced and your productivity increases.

FULLY AUTOMATED ROBOTIC BENDING SYSTEMS

TAM OTOMATİK ROBOTİK BÜKME SİSTEMLERİ

Ermaksan’s robotic press brake solutions take metal fabrication to the next level by seamlessly integrating advanced robotics with high-precision press brakes. This integrated system automates the entire bending cycle, from precise picking and bending to depositing sheet metal, effectively reducing manual handling and significantly boosting productivity and consistency.

Our robotic systems enable high-speed, repeatable bending processes, enhancing both quality and throughput. Designed for flexibility, Ermaksan’s robotic press brakes cater to a wide range of metal fabrication needs, ensuring precision while minimizing operator intervention. They also improve safety by reducing manual handling on the production floor.

Why Choose Ermaksan’s Robotic Bending Systems?

- Increased Productivity: Achieve faster, more consistent production cycles with automation.

- Enhanced Precision & Quality: Improve bending accuracy and ensure top-quality results with advanced robotic integration.

- Flexible Operations: Adapt to varying workloads and material specifications, easily handling complex bending tasks.

- Safety & Efficiency: Reduce manual intervention and enhance safety, maximizing both operator and workplace efficiency.

Streamline Your Bending Process with Ermaksan

Our robotic press brakes combine precision with automation to optimize your bending operations. By automating the entire bending cycle, Ermaksan’s solutions improve speed, accuracy, and overall performance, driving both productivity and flexibility.

Elevate your metal fabrication processes today with Ermaksan’s robotic press brake solutions—the future of automated metal bending technology.

IRIS PLUS LASER PROTRACTOR

IRIS PLUS LAZERLİ AÇI ÖLÇER

The IRIS Plus consists of a laser transmitter and receiver set mounted on the top beam of the press brake. The receiver unit includes a high-speed digital camera and image data processing system. This important device successfully performs real-time angle measurement and correction for the most demanding applications.

ERGONOMIC CONTROLLER ARM

ERGONOMİK KONTOLÖR KOLU

The ergonomic pendant arm allows smooth lateral and front-back movement, enabling the operator to adjust the control panel easily for optimal access. Ideal for workspaces where frequent repositioning is needed.

ERTOUCH 21

ERTOUCH 21

Standard Specifications

- 2D Display and 2D Programming

- Windows 10 LTE

- 256 GB Memory

- 2 USB Port

- 2D Display and 2D Programming Offline Software

- Product and Bending Counters

- Hemming and Air Bending

- Quick Help

- FMSC Safety System

- DSP – MCS Safety System

- LazerSafe Safety System

- Remote Access and Diagnostics

- 2 x GigE Ethernet

- 3D Display and 2D Programming Offline Software

- Multi-Touch Panel

- DXF – DWG Tooling Import/Export

- Stationary WorkWindows 10 LTE

- Unlimited Number of Product

- Unlimited Number of Materials

- Unlimited Number of Tooling

- Standard User Defined System

- List – Graphic Mode

- Reporting System

- 21,5” TFT monitor with 1920x1080 resolution

- Up To 12 Axis Control

- 3D Import, Rendering, STEP-IGES Product Import

- 3D Display and 3D Programming Offline Software

- DXF – DWG Product Import / Export

- Automatic Tool Placement

- Tool Segmantation System

- Horn System

- Special Curved Rotating Dies Support

- Network Product Sharing

- User Authorization System

Optional Specifications

- Keba Angle Protractor

- Barcode Reader

- 3rd Party Software Support

- ER 4.0

- Remote Service System

- Mitutoyo Angle Protractor

- Motorized Front Support (AP3 + AP4)

- Led Bar

- Robot Control

ERTOUCH 15 VISION

ERTOUCH 15 VISION

Standard Specifications

- Maximum 12 Axis

- 2D Display and 2D Programming

- Windows 10 LTE

- 256 GB Memory

- 2 USB Port

- 2D Display and 2D Programming Offline Software

- Product and Bending Counters

- Hemming and Air Bending

- Quick Help

- FMSC Safety System

- DSP – MCS Safety System

- LazerSafe Safety System

- Remote Access and Diagnostics

- 2 x GigE Ethernet

- 3D Display and 2D Programming Offline Software

- Multi-Touch Panel

- DXF – DWG Tooling Import/Export

- Stationary WorkWindows 10 LTE

- Unlimited Number of Product

- Unlimited Number of Materials

- Unlimited Number of Tooling

- Standard User Defined System

- List – Graphic Mode

- Reporting System

Optional Specifications

- User Defined System

- Keba Angle Protractor

- Barcode Reader

- 3rd Party Software Support

- User Authorization System

- ER 4.0

- Remote Service System

- Mitutoyo Angle Protractor

- User Authorization System

- Keba Angle Protractor

- Motorized Front Support (AP3 + AP4)

- Led Bar

- Robot Control

COBOT-INTEGRATED BENDING SYSTEMS

COBOT ENTEGRELİ BÜKME SİSTEMLERİ

Discover the next generation of sheet metal bending with Ermaksan’s press brakes, seamlessly integrated with advanced cobot solutions. These cobot-powered systems manage material feeding, positioning, and secure holding, enabling precise and efficient bending processes. This integration enhances productivity, simplifies complex tasks, and optimizes production workflows, saving valuable time and resources.

Designed for modern manufacturing, our cobot-integrated press brakes offer flexible, efficient solutions—even for intricate bending requirements. Featuring an intuitive, user-friendly interface, these cobots are easy to program and require minimal training. Setting up a bending sequence is as simple as placing the cobot in free-drive mode: the operator guides the cobot through each step while the software records the precise movements and speeds.

A unique feature of our cobots is the two control buttons on the 6th axis, where the vacuum holder is located. By pressing these buttons, the operator can move the robot manually, guiding its trajectory without needing a teach pendant or specialized software knowledge. The cobot’s sensors respond to the force applied by the operator, allowing easy, hands-on teaching of the bending path. This approach removes the need for conventional programming, making automation accessible to all users. Manual operation can also be resumed anytime without requiring major adjustments.

The system is CE-compliant and can operate safely alongside the operator without light or safety barriers, as the robot stops immediately upon any impact. Ermaksan’s cobot-integrated press brakes bring flexibility, cost-efficiency, and optimized performance to your manufacturing operations, empowering you to elevate productivity with ease.

Choosing a cobot-integrated bending system allows you to enjoy the benefits of automation without the significant upfront costs and safety requirements associated with traditional robotic cells.

SLIDING DOOR REAR GUARD

SÜRGÜLÜ ARKA KORUMA

This manually operable horizontal sliding rear guard is available in custom colors, including body-matched or safety orange. It is designed to restrict access to the rear hazard zone of the press brake while allowing for simple manual operation.

Integrated safety switches halt machine operation when the door is not fully closed, ensuring operator safety and conformity with CE machinery safety directives.

MITUTOYO UNIVERSAL ANGLE GAUGE

MITUTOYO UNIVERSAL AÇI ÖLÇER

- Can easily read measurements through a clear screen.

- Can easily transfer your measurement data to the controller with its Bluetooth feature and provide correction to the value to obtain more accurate results.

- When not active, it will turn itself off after 10 minutes and save up to 200 hours of battery.

DELEM DA - 69S

DELEM DA - 69S

- 3D and 2D Graphic Touch Screen Programming Mode

- 3D and 2D Imaging in Simulation and Manufacturing

- 24” high-resolution color TFT display

- Fully Equipped Windows App

- Profile-T3D Offline Software

- 4 GB Memory

- Product and Tool Memory

- USB flash Memory Drive

- 2D and 3D Automatic Bending Sequence Calculation

- Programmable Material Specifications

- Programmable Axis Speeds

- Free Material Programming

- Product and Tool Search Filters

- Millimeter / Inch, kN / Ton Selection

- Stock Counter

- Graphic Tool Configuration

- Emergency Stop Button

- Graphical Product and Tool Selection

DELEM DA - 66S

DELEM DA - 66S

- 3D(O) and 2D Graphic Touch Screen Programming Mode

- 2D+ and 2D Imaging in Simulation and Production

- 24” high-resolution color TFT display

- Fully Equipped Windows App

- Profile-LT Offline Software

- 4 GB Memory

- Product and Tool Memory

- USB flash Memory Drive

- 2D and 2D+ Automatic Bending Sequence Calculation

- Programmable Material Specifications

- Programmable Axis Speeds

- Free Material Programming

- Product and Tool Search Filters

- Millimeter / Inch, kN / Ton Selection

- Stock Counter

- Graphic Tool Configuration

- Emergency Stop Button

- Graphical Product and Tool Selection

ESA S875 W

ESA S875 W

- DXF Part and Tool Retrieval (O)

- 21” Multi-touch Screen

- Advanced HDMI and Easy Learning

- Up to 12 Axis Control

- Full HD Multitouch Resistive Color Screen

- Standard 2 Ethernet Ports

- 3D Imaging

- 2D Programming

ESA S860 W

ESA S860 W

- 19” Multi-touch Display

- Top and Bottom Mold Holder Management

- Download Files with .Dxf Extension and Tool Library Management (O)

- Up to 12 Axis Control in Combination

- 3D CAD/CAM Image and Fingertip Job Design

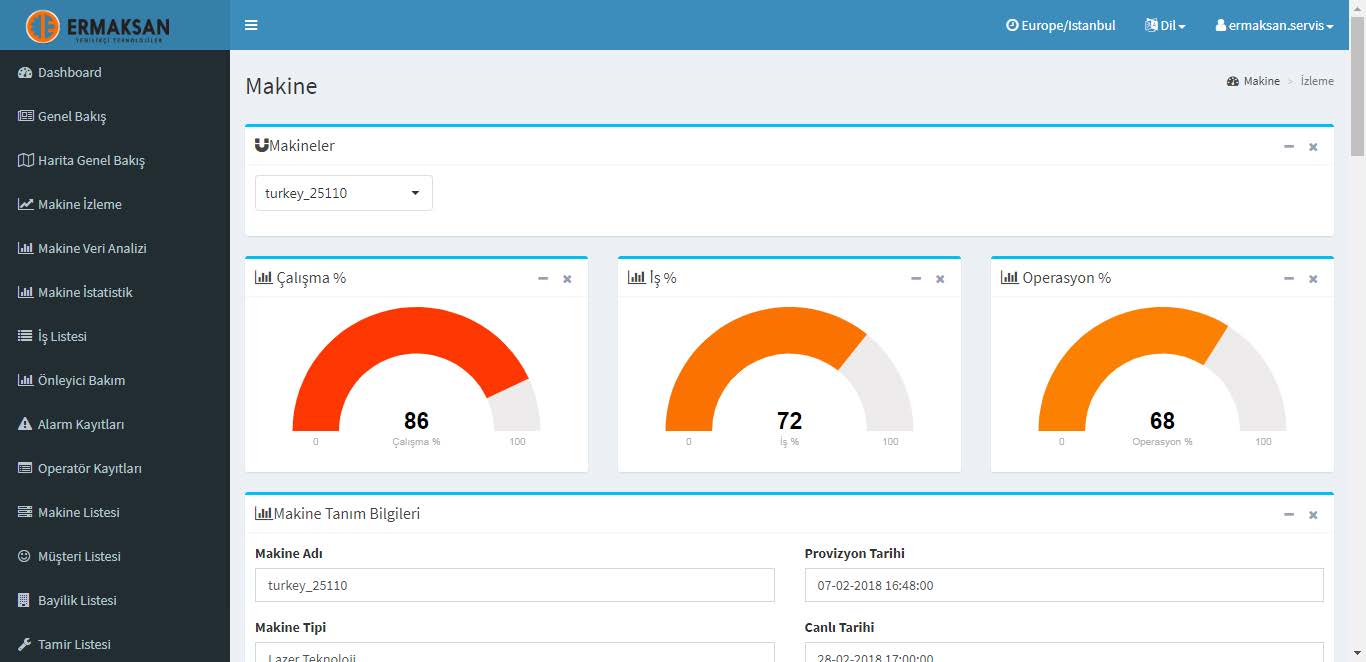

ER 4.0 – INDUSTRY 4.0

ER 4.0 – ENDÜSTRİ 4.0

ER 4.0 is Ermaksan’s proprietary Industry 4.0 software solution designed to digitalize sheet metal processing machines and production equipment. It provides real-time monitoring, performance analytics, and process optimization, enabling manufacturers to take full control of their operations through smart and connected technologies.

With its intuitive interface, ER 4.0 collects and visualizes machine data from the shop floor to help manufacturers make informed decisions and increase productivity. Its ability to integrate with ERP systems builds a seamless digital bridge between operations and management, supporting data-driven efficiency across the organization.

Key Benefits:

- Real-time traceability and data-driven decision-making

- Enhanced machine and process efficiency

- Downtime tracking for production lines

- Digital maintenance and performance tracking

- Easy integration with ERP systems

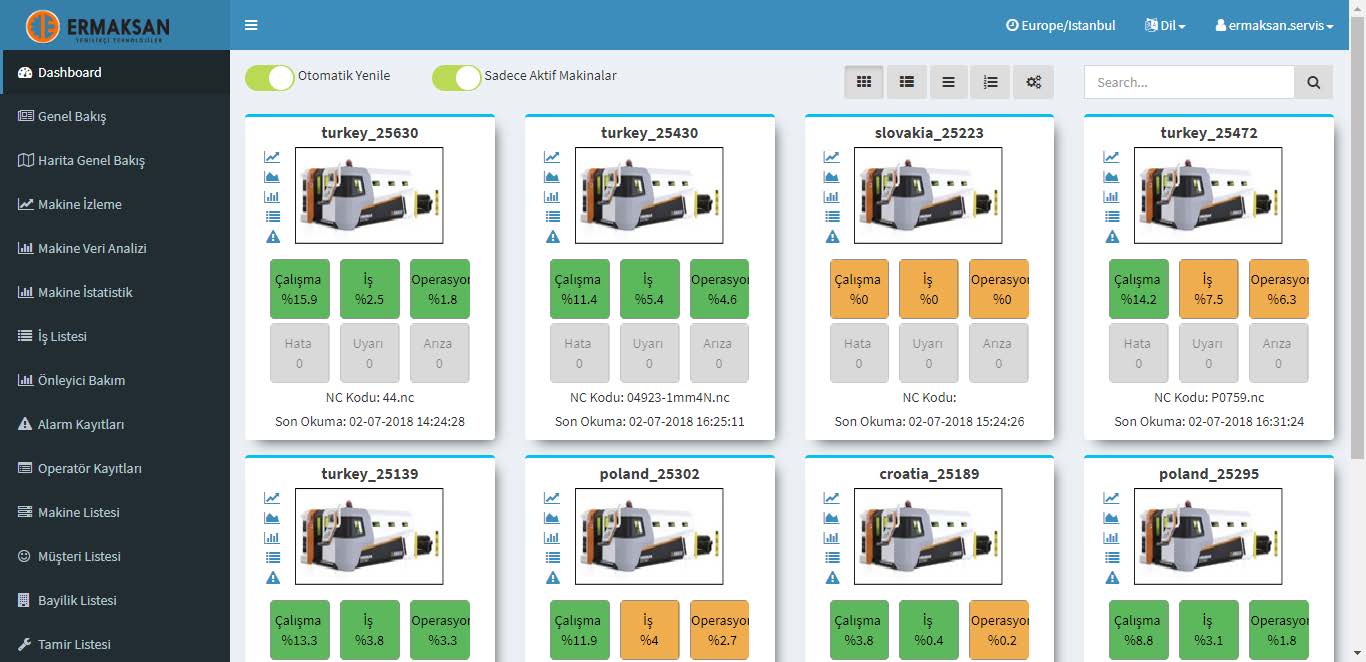

ALL INTEGRATED

Integrate your machine data with your MES and ERP applications.

ALL THE DATA

Record your machine historic performance data. Track your machine Job and Operator performance.

ALL THE MACHINES

Enable all your production line to be monitored. Retrofit you existing machines to our Industry 4.0 platform.

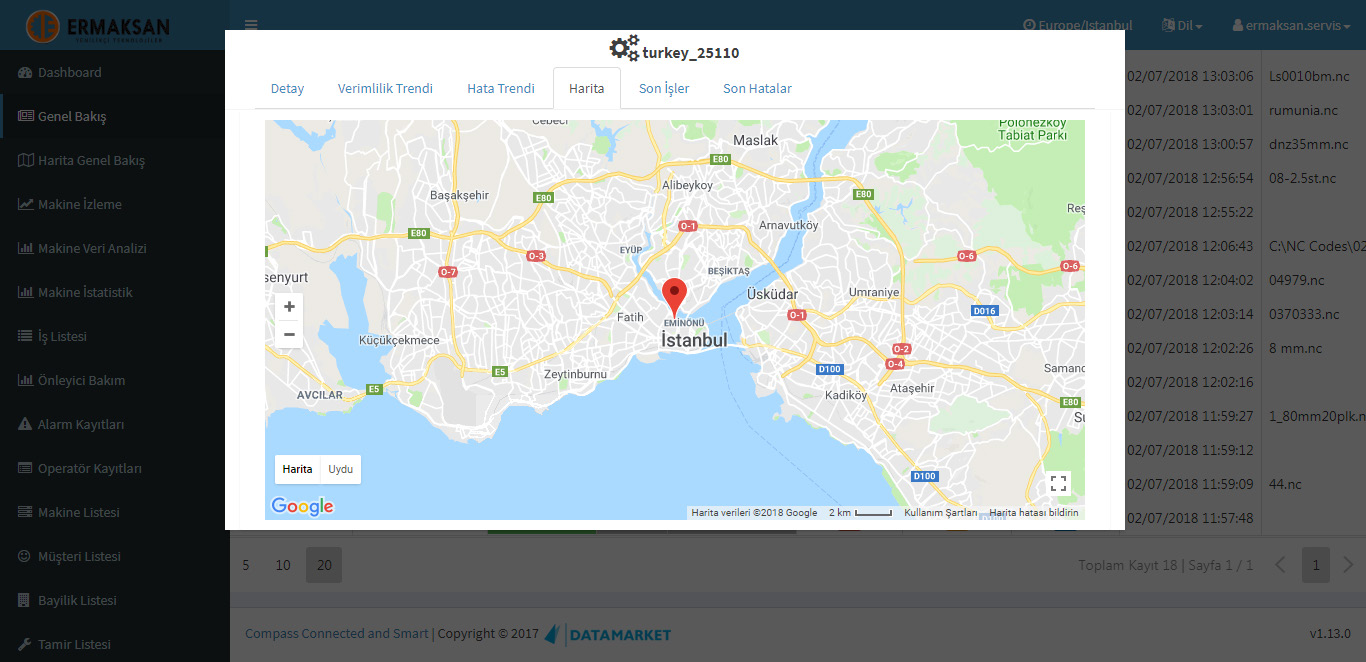

ANY WHERE

Monitor and track machine performance over the flexible easy to use WEB interface from any where

ANY TIME

Reach your machine performance data any time you like.

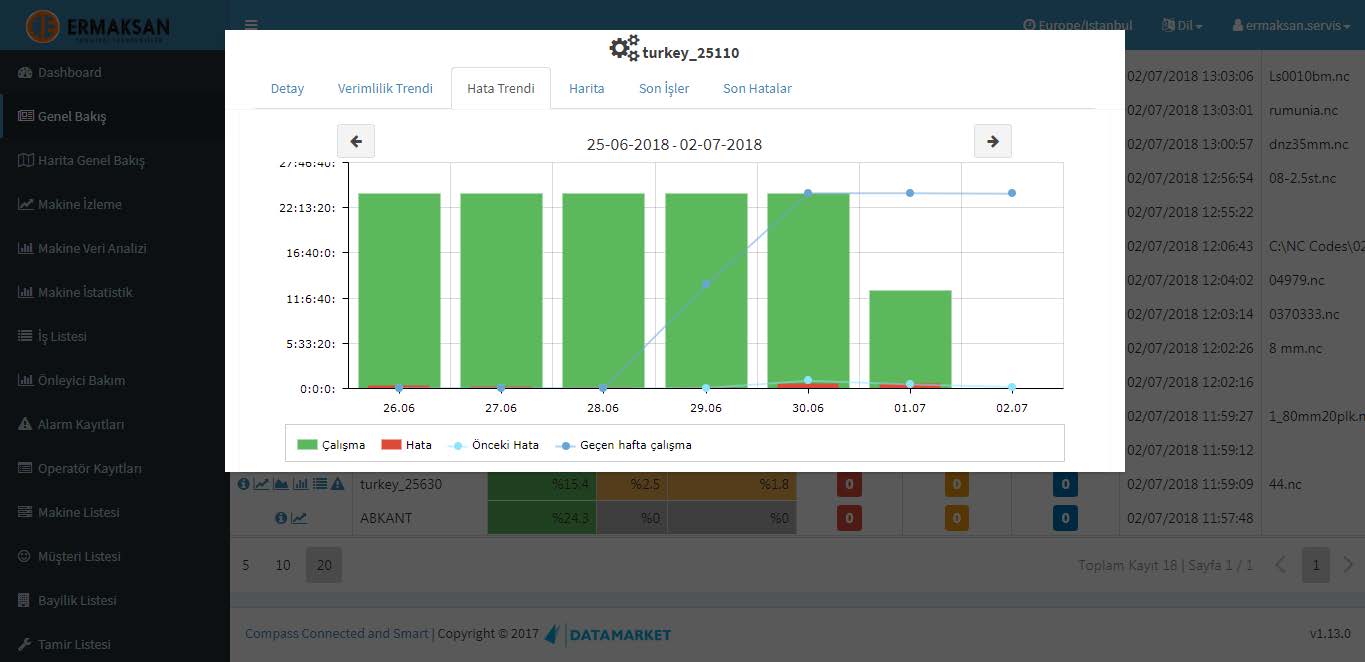

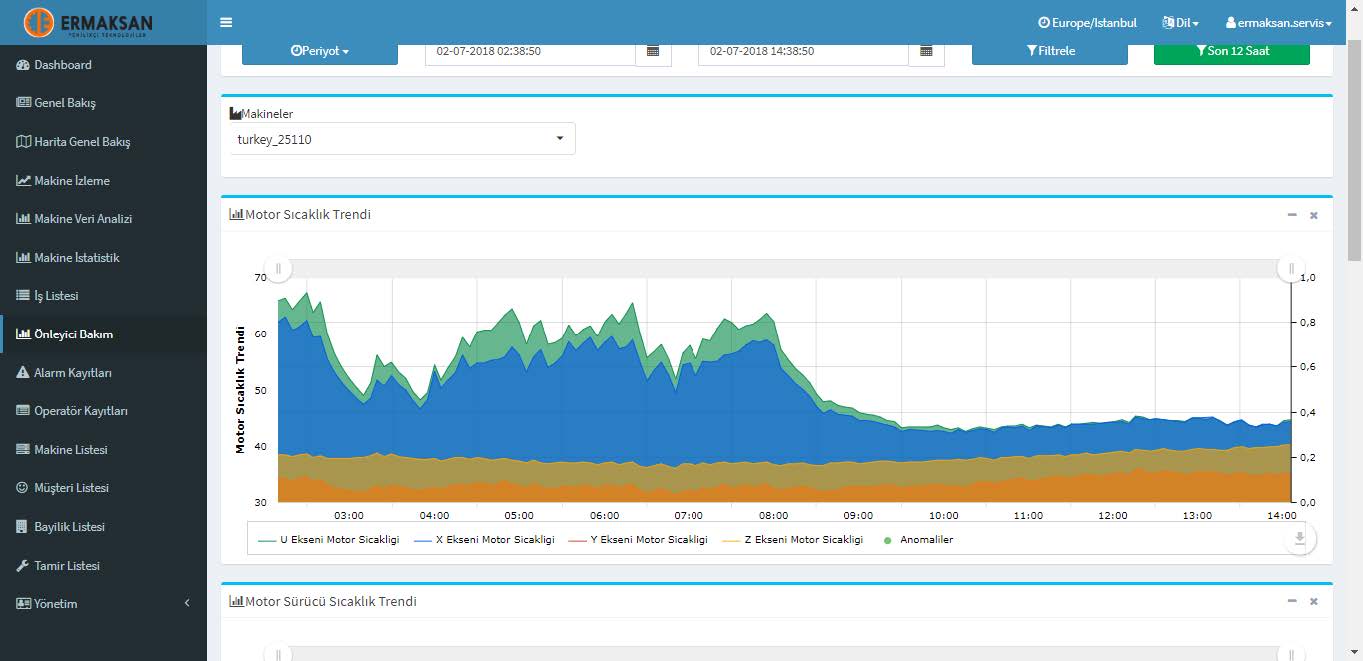

EFFICIENCY GRAPH OF THE MACHINE FOR THE LAST WEEK

Generates a trend graph by compiling the operational information of the machine. Operation performance for the previous week may be monitored.

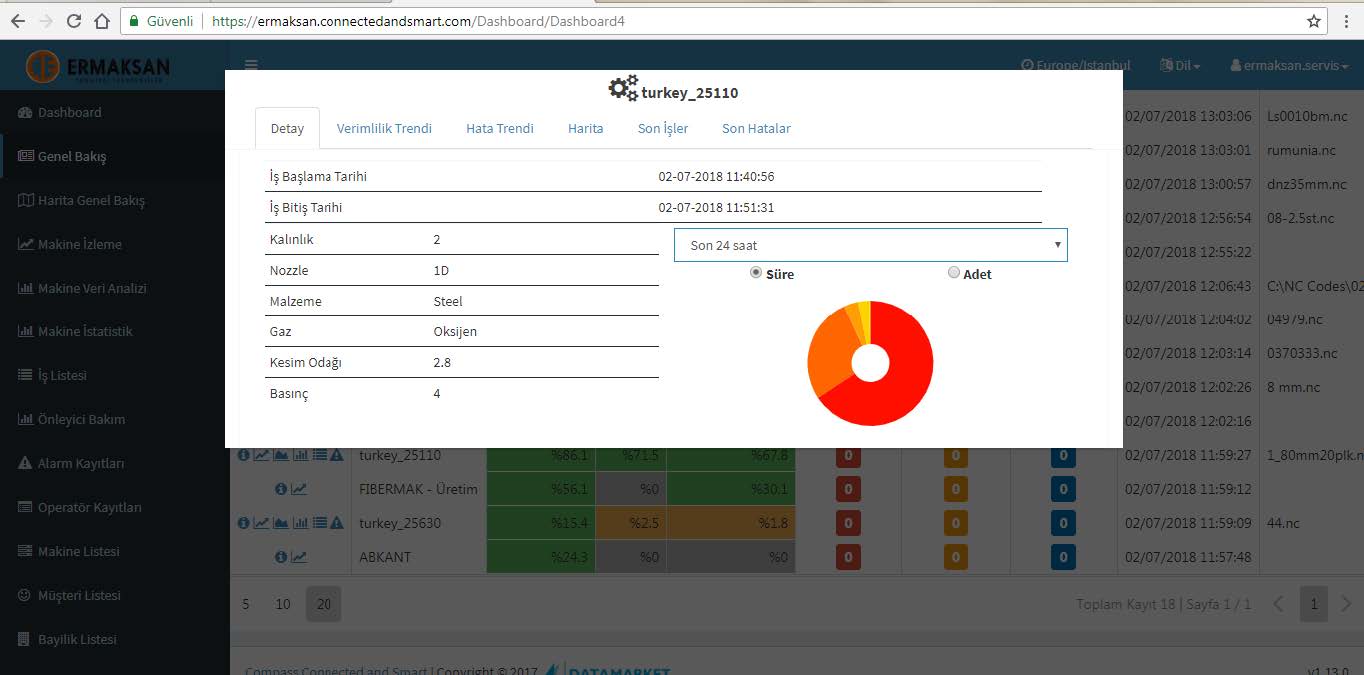

DETAILED INFORMATION OF THE LAST WORK COMPLETED

Indicates all the details of the work done, and information such as how long it did take the operator to complete which work and in what way.

OEE VALUES OF THE MACHINE

Collects all the information during the stand-by, production and preparation processes to generate a general productivity chart.

EQUIPMENT DATA

It shows the instantaneous data of the operational elements of the machines as trend graph.

MACHINE MONITORING SCREEN

You may monitor your machines in different fields from a single screen.

STATUS OF THE MACHINES

This provides the lists of the operational and non-operational machines on the field and the summary of their operation.