EPL 3/5 AXIS PLASMA

HIGH CUTTING QUALITY

The XPR series combines advanced X-Definition™ technology with cutting-edge processes to deliver outstanding precision and superior edge quality on mild steel, stainless steel, and aluminum.

LONG-TERM SAVINGS

Intelligent power supply technology with real-time feedback continuously optimizes performance, extending consumable life and reducing both maintenance and operational costs in the long run.

LOW ENERGY CONSUMPTION

Designed with energy efficiency in mind, our systems reduce resource consumption while maximizing productivity. Lower energy usage not only cuts costs but also contributes to a more sustainable future.

EASY OPERATION

Automatic adjustment of cutting parameters simplifies the process in a single step. By minimizing operator intervention, the system ensures consistent, high-quality results every time.

LOW OPERATING COSTS

Extend consumable life by over 40% and reduce operating costs by more than 50%. Our technology delivers exceptional cost efficiency and long-term value.

FLEXIBLE SOLUTIONS

Our systems adapt easily to various automation requirements, offering flexible and scalable solutions with a user-friendly design. They integrate seamlessly into your processes, enhancing both efficiency and convenience.

SUBSCRIBE E-NEWSLETTER

You can subscribe to the e-bulletin to receive information regarding the developments about Ermaksan

I-CUT PLATE + PIPE + PROFILE

I-CUT PLATE + PIPE + PROFILE

In addition, it optionally cuts pipes between 100 - 600 mm. In pipe cutting, there is a wide application area in structures such as tanks, pipelines, power plants.

It is designed to meet the sector's pipe cutting needs on steel construction in the best way.

These machines have a wide range of uses such as construction sector, defense and machinery industries.

I-CUT PLATE + PIPE

I-CUT PLATE + PIPE

In addition, it optionally cuts pipes between 100 - 600 mm. In pipe cutting, there is a wide application area in structures such as tanks, pipelines, power plants.

It is designed to meet the sector's pipe cutting needs on steel construction in the best way.

These machines have a wide range of uses such as construction sector, defense and machinery industries.

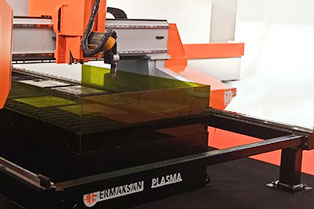

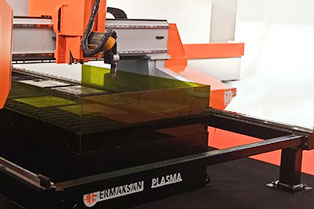

I-CUT PLATE

I-CUT PLATE

The wide-base software for plasma and the user-friendly CNC controller provide great convenience for the operator.

R&D engineering studies have been meticulously applied in the main body and movable bridge of the EPL plasma cutting machine, which ensures high cutting quality.

The EPL Plasma Series is the machine with the most ideal consumable consumption on the market. Ermaksan in consumables and spare parts; Hypertherm offers its customers very special price advantages in materials.

TRUE BEVEL + TRUE HOLE + BEVEL PIPE + BEVEL PROFILE

TRUE BEVEL + TRUE HOLE + BEVEL PIPE + BEVEL PROFILE

It also optionally cuts pipes between 100 and 600 mm. In pipe cutting, there is a wide application area in structures such as tanks, pipelines, power plants. It makes angled cuts with 5 axis cutting heads.

It is designed to meet the sector's pipe cutting needs on steel construction in the best way. These machines have a wide range of uses such as construction sector, defense and machinery industries. True Hole™ technology for carbon steel is only available on the XPR 300 and HPR XD® plasma systems with automatic gas console.

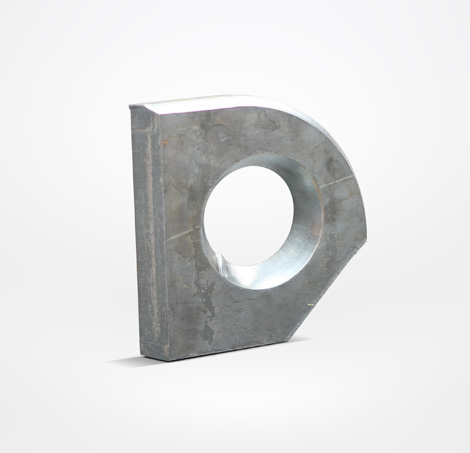

The patented True Hole™ technology developed for carbon sheet metal is a specific combination of optimized cutting parameters for different hole sizes and material thicknesses. True Hole™ technology completely eliminates angles and distortions in the holes.

With True Hole, you get more consistent part design dimensions,™ which means less secondary operations are required. Compared to other plasma systems on the market, True Hole™ technology provides up to 50% improvement in cylinder holes drilled in carbon steel.

TRUE BEVEL + TRUE HOLE + BEVEL PIPE

TRUE BEVEL + TRUE HOLE + BEVEL PIPE

In addition, it optionally cuts pipes between 100 - 600 mm. In pipe cutting, there is a wide application area in structures such as tanks, pipelines, power plants. Construction in profile cutting, defense. It makes angled cuts with 5 axis cutting heads.

True Hole™ technology for carbon steel is only available on the XPR 300 and HPR XD® plasma systems with automatic gas console. The patented True Hole™ technology developed for carbon sheet metal is a specific combination of optimized cutting parameters for different hole sizes and material thicknesses.

True Hole™ technology completely eliminates angles and distortions in the holes. With True Hole, you get more consistent part design dimensions,™ which means less secondary operations are required.

Compared to other plasma systems on the market, True Hole™ technology provides up to 50% improvement in cylinder holes drilled in carbon steel.

It is designed to meet the sector's pipe cutting needs on steel construction in the best way. These machines have a wide range of uses such as construction sector, defense and machinery industries.

TRUE BEVEL + TRUE HOLE

TRUE BEVEL + TRUE HOLE

In pipe cutting, there is a wide application area in structures such as tanks, pipelines, power plants. Construction in profile cutting, defense. It makes angled cuts with 5 axis cutting heads. True Hole™ technology for carbon steel is only available on the XPR 300 and HPR XD® plasma systems with automatic gas console.

The patented True Hole™ technology developed for carbon sheet metal is a specific combination of optimized cutting parameters for different hole sizes and material thicknesses. True Hole™ technology completely eliminates angles and distortions in the holes.

With True Hole, you get more consistent part design dimensions,™ which means less secondary operations are required. Compared to other plasma systems on the market, True Hole™ technology provides up to 50% improvement in cylinder holes drilled in carbon steel.

It is designed to meet the sector's pipe cutting needs on steel construction in the best way. These machines have a wide range of uses such as construction sector, defense and machinery industries.

IHT M4000 CAP – AUTOMATIC GAP CONTROL

IHT M4000 CAP

The IHT M4000 CAP provides precise, automatic gap control for oxy-fuel cutting machines. Its robust design ensures reliable, non-contact operation, achieving consistent, high-quality dry cuts backed by built-in IHT technology.

The system consists of a Linear Drive Body Cover, a Guide Rail (available in three different lengths), and a Control Unit Cover with integrated capacitive sensors and a motor controller. A ring electrode measures the distance to the metallic workpiece, while the Linear Drive Cable transfers power, CNC signals, and adjustment data from the remote control potentiometer.

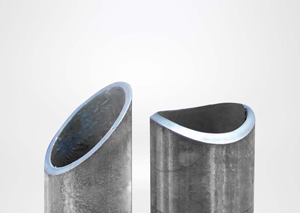

STRAIGHT PIPE CUTTING

PROFİL VE BORU KESİM

IMPRESSIVE SOLUTIONS FOR TUBE CUTTING...

Ermaksan has designed EPL Plasma series to cut tubes from 50 to 400 mm in diameter precisely with its tube cutting technology. Cuts profiles between 100 and 600 mm. Tube cutting has a wide range of application such as tanks, pipe lines, power plants, etc. Profile cutting is used for construction, defence industries, and it provides angled cuts with the 5-axis cutting head provided optionally if desired.

It is designed to meet the tube cutting requirements of the industry on steel construction in the best way. These machines are used in a wide range from construction industry to defence and machinery industries.

|

|

Rotary Tube ProTM provides a complete design and cutting solution for tube and pipe parts without the need for 3D CAD experience. Using standard parameters, tubes and branches can be easily identified within the software interface. Side wall silhouettes can be added from CAD or from a list of pre-defined shapes.

- Sensitive and qualified cuts with Hypertherm XD® plasma source

- Meeting the high speed plasma cutting standards with impeccable filtration system thanks to inner pipe suction design.

- High precision for edge cuts and round cuts with the milled teeth helical rack and pinion.

- Manual support system that provides 50 – 400 diameter pipe cuts.

- Advanced Height control unit designed for plasma cutting.

- A design that protects mechanical parts from fumes or impacts.

- EDGE Connect CNC control unit is easy to use and efficient

- Sofware Rotary TubePro Cad/Cam

- Marking speciality

- Feature of returning backward and continue to cut where ever needed.

- Large utilization area like tank manufacturing, pipe line etc.

Rotary Tube ProTM supports almost all tube cutting machine brands, including stand-alone units and cutting table add-ons. The software supports bevel cutting as a standard feature and bevel cutting as an optional module.

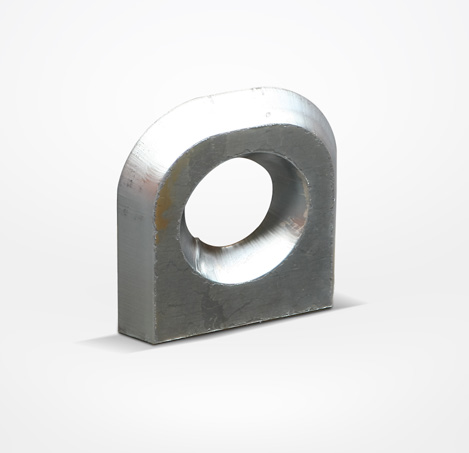

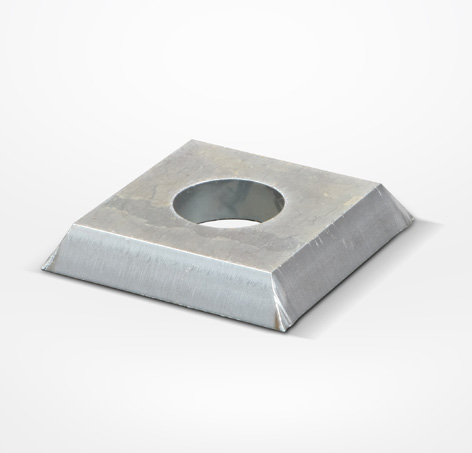

TRUE HOLE

TRUE HOLE

Patented True HoleTM technology which was developed for carbon sheet, is a specific combination of cutting parameters which were

optimised according to different hole sizes and material thicknesses.

With True HoleTM, you acquire more consistent part dimensions and hence you need fewer second operations.

When this technology is compared with other plasma systems in the market, it provides enhancement in quality up to 50% in cylinder

holes opened on carbon steel.

How is True Hole Technology obtained?

Achieved with EDGE® Connect Controller, Ermak THC, HPRXD®, XPR, Automatic gas system and ProNest® nesting software and well-matched cutting table.

True HoleTM technology of Hypertherm is a special combination of cutting parameters optimised for every single material thickness and hole dimensions

- Performed gas type

- Gas flow

- Amper

- Drilling method

- Input/output technique

- Cutting speed

- Timing

ERMAK THC – TORCH HEIGHT CONTROL

ERMAK THC – Torç Yükseklik Kontrolü

The ERMAK THC (Torch Height Control) system delivers superior cutting precision and extended consumable life through advanced arc voltage sampling and control technology. By minimizing cut-to-cut cycle time, it boosts part production by up to 80% per hour.

Featuring robust mechanics covered under a 2-year warranty and an easy-to-use human–machine interface, setup adjustments can be completed in under a minute. Performance advantages are achieved with minimal operator input, reducing the need for extensive training and ensuring consistent, high-quality results across all shifts and operators.

CONTROL PANEL

KONTROL PANELİ

The standard control panel is mounted directly on the bridge and moves along with it. This design provides operators with continuous access and control throughout the cutting process. With its ergonomic structure, it ensures ease of use, safety, and efficiency.

HYPERTHERM XPR170 POWER SOURCE

HYPERTHERM XPR170 GÜÇ KAYNAĞI

Widest versatility expands capabilities

Industry leading cut quality–X-Definition The XPR advances HyDefinition® cut quality by blending new technology with refined processes for next generation, X-Definition™ cutting on mild steel, stainless steel and aluminum.

- Superior stainless steel cut quality

- Consistent ISO range 2 results on thin mild steel and extended range 3 cut quality on thicker mild steel and stainless steel

- Superior results on aluminum using Vented Water Injection ™ (VWI)

Optimized productivity and reduced operating costs

- Significantly lower operating costs than previous generation technology

- Dramatic improvement in consumable life on mild steel applications

- Thicker piercing capability than competitive plasma systems

Engineered system optimization and ease of use

- Ramp down error protection significantly increases realized consumable life

- Automatic system monitoring and specific troubleshooting codes for improved maintenance and service prompts

- EasyConnect™ torch lead and one hand torch-to-receptacle connection for fast and easy change‑outs

- QuickLock™ electrode for easy consumable replacement

- WiFi in the power supply can connect to mobile devices and network mode for multiple system monitoring and service

| Mild steel | mm | inches |

|---|---|---|

| Production pierce capacity (air shield gas) | 35 | 1-3/8 |

| Enhanced pierce capacity (argon-assist shield gas)* | 40 | 1-9/16 |

| Severance | 60 | 2-3/8 |

| Stainless steel | ||

| Pierce capacity | 22 | 7/8 |

| Severance | 38 | 1-1/2 |

| Aluminum | ||

| Pierce capacity | 25 | 1 |

| Severance | 38 | 1-1/2 |

* Argon-assist technology for thicker piercing is available with CorePlus, VWI and OptiMix gas consoles.

HYPERTHERM XPR300 POWER SOURCE

HYPERTHERM XPR300 GÜÇ KAYNAĞI

Widest versatility expands capabilities

Industry leading cut quality–X-Definition The XPR advances HyDefinition® cut quality by blending new technology with refined processes for next generation, X-DefinitionTM cutting on mild steel, stainless steel and aluminum.

- Consistent ISO range 2 results on thin mild steel and extended range 3 cut quality on thicker mild steel and stainless steel

- Superior results on aluminum using Vented Water InjectionTM (VWI)

Optimized productivity and reduced operating costs

- Significantly reduced operating costs than previous generation technology

- Increased cut speeds on thicker materials

- Dramatic improvement in consumable life on mild steel applications

- Thicker piercing capability than competitive plasma systems

Engineered system optimization and ease of use

- Ramp down error protection significantly increases realized consumable life

- Reduces the impact of catastrophic electrode blowouts which can damage the torch at high current levels

- Automatic system monitoring and specific troubleshooting codes for improved maintenance and service prompts

- EasyConnectTM torch lead and one hand torch-to receptacle connection for fast and easy change-outs

- QuickLockTM electrode for easy consumable replacement

- WiFi in the power supply can connect to mobile devices and network mode for multiple system monitoring and service

| Mild steel | mm | inches |

|---|---|---|

| Production pierce capacity (air shield gas) | 45 | 1-3/4 |

| Enhanced pierce capacity (argon-assist shield gas)* | 50 | 2 |

| Severance | 80 | 3-1/8 |

| Stainless steel | ||

| Pierce capacity | 38 | 1-1/2 |

| Severance | 75 | 3 |

| Aluminum | ||

| Pierce capacity | 38 | 1-1/2 |

| Severance | 50 | 2 |

* Argon-assist technology for thicker piercing is available with CorePlus, VWI and OptiMix gas consoles.

EMERGENCY STOP CABLE AROUND THE GANTRY

KÖPRÜ ETRAFI GÜVENLİK KABLOSU

The Emergency Stop Cable runs around the gantry, allowing the machine to be stopped immediately when the cable is pulled by the operator or anyone nearby. This simple yet effective safety feature provides quick response capability in case of any undesired condition, improving workplace safety during cutting operations.

LIGHT BODYGUARD

IŞIKLI KORUMA PERDESİ

The Light Bodyguard system uses the Leuze M4000 backlight protection curtain, which meets CE safety standards. It creates a protective optical barrier that detects any unauthorized movement in the cutting area and immediately halts machine operation if triggered. This ensures a safer working environment without compromising productivity.

BODYGUARD CAAF

KAFESLİ KORUMA SİSTEMİ

The Bodyguard CAAF cage barrier system is installed around the machine to prevent external access to moving parts. This protective enclosure minimizes the risk of accidental contact and enhances overall operator safety. Its modular design allows easy maintenance access when needed, ensuring both safety and operational continuity.

WATER TABLE

SULU TABLA

The Water Table is designed to be filled with water up to the surface of the plate, effectively capturing dust, smoke, and heat generated during cutting. This system reduces thermal deformation on thin materials and minimizes noise and airborne particles, creating a cleaner and safer working environment. It is especially beneficial when cutting thin sheets, ensuring smooth and accurate results.

PORTAL TABLE

PORTAL TABLA

The Portal Table is designed for larger machine sizes and heavy-duty operations. By fixing the machine rails and body to the ground, it ensures maximum rigidity and stability during cutting. This robust structure allows precise results even under demanding industrial conditions and provides long-term reliability for continuous production.

COMPACT TABLE

KOMPAKT TABLA

The Compact Table combines the cutting table and machine body into a single integrated structure, providing a compact and robust design for smaller models. This configuration reduces installation space, simplifies setup, and makes the machine easier to transport. It is an ideal choice for businesses seeking efficient use of space without compromising cutting performance.

ELECTRIC PANEL COOLER

ELEKTRİK PANOSU SOĞUTUCUSU

The Electric Panel Cooler maintains the ideal operating temperature inside the electrical cabinet, ensuring stable and reliable performance of all electronic components. Depending on the working environment, either a cooling or heating unit can be integrated to protect the system from overheating or condensation.

By keeping internal temperatures consistent, this system extends the lifespan of sensitive electronics and reduces the risk of unexpected downtime, providing reliable operation even in demanding industrial conditions.

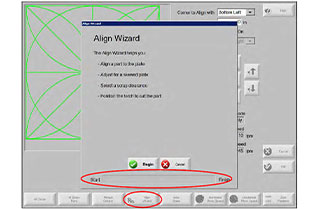

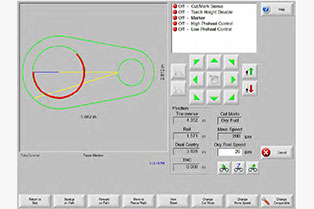

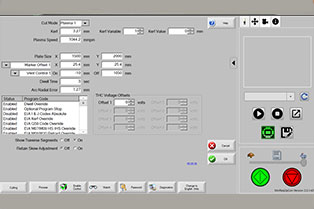

HYPERTHERM EDGE CONNECT TC CONTROLLER

HYPERTHERM EDGE CONNECT TC KONTROLÖR

The Hypertherm EDGE Connect TC Controller represents the latest generation of CNC control technology, delivering unmatched reliability, advanced integration, and superior process control. Powered by Hypertherm’s Phoenix® software, it provides a consistent interface across the entire CNC family, ensuring ease of use and seamless operation.

Designed for maximum performance, the EDGE Connect TC offers precise motion control, intelligent process monitoring, and full compatibility with plasma and oxy-fuel cutting systems. Its modular architecture and network connectivity make it ideal for Industry 4.0 applications, enabling data-driven production management and remote diagnostics.

MARKING PEN

MARKALAMA KALEMİ

The Marking Pen is a pneumatic marking tool designed for engraving texts, serial numbers, or figures on flat metal surfaces. Using a hard-tipped stylus, it creates precise dot impressions, enabling permanent and traceable part marking without affecting material integrity.

Ideal for industrial applications, the system operates quickly and efficiently, supporting part identification and production traceability. Its robust design ensures long-lasting performance even under continuous operation.

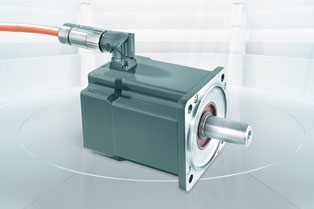

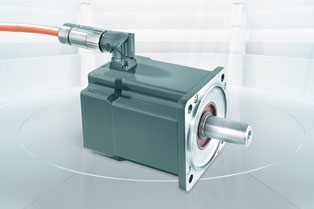

MITSUBISHI DIGITAL AC SERVO MOTOR

MITSUBISHI DIGITAL AC SERVO MOTOR

The Mitsubishi Digital AC Servo Motor system provides high-speed, accurate, and stable motion control for plasma cutting operations. It uses a dual-drive synchronous configuration on the Y-axis and a single-drive system on the X-axis, both meeting CE and CSA standards.

These advanced servo motors ensure smooth movement, precise positioning, and long-term durability even in continuous heavy-duty production. Their dynamic response and energy-efficient design contribute to higher cutting accuracy and operational efficiency, making them an essential component of Ermaksan’s precision engineering.

OXY CUT ±45° MANUAL ANGLE CUTTING APPARATUS

OXY CUT ±45° MANUEL AÇI APARATI

The OXY CUT ±45° Manual Angle Cutting Apparatus allows the oxygen cutting torch to perform bevel cuts up to ±45° in both horizontal and vertical planes.

This manual system provides precise and flexible operation, making it ideal for workshops that frequently require angled or chamfered edges. Its robust and ergonomic design ensures easy adjustment and consistent accuracy throughout cutting processes.

VWI GAS CONSOLE

VWI GAZ KONSOLU (OTOMATİK)

In non-ferrous materials, especially aluminum, the edges are steep, the angulation problem is low and the surface finish is excellent.

CORE CONSOL

CORE KONSOL

This is delivered through a new N2 HDiTM process that prevents the mixing of air into the plasma gas, creating an improved, brighter edge finish.

STANDARD BRIDGE MANUAL ± 45° ANGLE CUTTING APPARATUS

STANDART KÖPRÜLÜ MANUAL ±45° AÇILI KESİM APARATI

Users cannot cut full width with angle cutting.

EXPANDED BRIDGE MANUAL ± 45° ANGLE CUTTING APPARATUS

GENİŞLETİLMİŞ KÖPRÜLÜ MANUAL ±45° AÇILI KESİM APARATI

In this case, the machine can cut the sheet that can be cut to the maximum dimensions of full width and length.

POINT LASER LIGHT FEATURE

NOKTA LAZER IŞIĞI ÖZELLİĞİ

At the same time, this plate gives us a huge advantage in alignment.

NETWORK INTERFACES AND USB PORT FEATURE

AĞ ARA YÜZLERİ VE USB PORTU ÖZELLİĞİ

Thanks to the USB ports, program installation can be made to the machine.

AUTOMATIC CUTTING HEIGHT CORRECTION SOFTWARE

OTOMATİK KESİM YÜKSEKLİK DÜZELTME YAZILIMI

It is combined with the use of software and electronic parts.

NEUGART PLANET TYPE REDUCER

NEUGART PLANET TİP REDÜKTÖR

3 AC Brushless Servo motors of American/German/Japanese origin in accordance with CE and CSA standards, and high performance gapless planetary type gearbox are used, including double drive synchronous in Y Axis and single in X axis.

ROTARY TUBE PRO™ SOFTWARE

ROTARY TUBE PRO™

An easier way to design and cut tubes

Rotary Tube Pro™ offers a complete design and cut solution for tube and pipe parts in mechanized cutting applications including plasma, laser, and oxyfuel. There is no 3D CAD experience required. Tubes and branches are easily created using parametric input. Side‑wall cut outs can be selected from a list of pre-defined shapes, or added from CAD. And, if necessary, users can import 3D CAD files. This flexibility allows fabricators and manufacturers to work more efficiently, boost productivity, and reduce operating costs.

In addition, Rotary Tube Pro supports virtually all brands of tube cutting machine, including stand-alone units and cutting table add-ons. It supports perpendicular cutting as a standard feature and bevel cutting as an optional module.

Standard feature highlights:

- Cut process support for plasma, and oxyfuel

- Part creation and development

- Automatic nesting

- Common line cutting

- SureCut™ technology capable including True Hole®

- Reporting with detailed job information

- Simplified costing

- Output with advanced post-processor

- Bevel cutting option

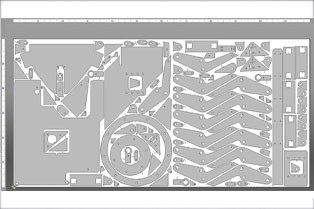

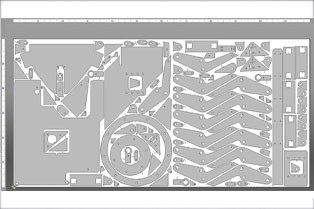

PRONEST® SOFTWARE

PRONEST®

Material cost savings

ProNest CAD/CAM part nesting software for advanced mechanized cutting is designed to supercharge your cutting operation, helping you achieve greater automation, efficiency, and profitability. Brought to you by the cutting experts at Hypertherm Associates, ProNest can optimize performance for plasma,and oxyfuel cutting machines. More than just a nesting software, ProNest includes powerful features to help manage your entire cutting operation. You’ll be able to quote jobs, manage work orders, and monitor machine status, all in one

place.

Optimized for XPR and HPR XD Series

ProNest is engineered in close alignment with Hypertherm’s world-famous XPR® and HPR XD® plasma systems. This advanced integration ensures that you get the absolute best in cut quality, productivity, and efficiency, pushing your machine's capabilities to the highest level.

MATERIAL COST SAVINGS

Powerful, high yield nesting reduces your material costs and increases profitability.

EASE OF USE

Incredibly easy to learn and use, with intuitive screens, and a wide variety of helpful features.

BREAKTHROUGH TECHNOLOGIES

ProNest is the only software that provides full support for our Sure-Cut™ technologies including True Hole®, Rapid Part™, and PlateSaver™ which are delivered automatically without operator intervention, and True Bevel™ which greatly reduces bevel set up time.

INCREASED PRODUCTIVITY

Modules like Common Line Cutting and Chain and Bridge Cutting can increase efficiency, and reduce cutting time and consumable wear.

UNLIMITED TECHNICAL SUPPORT

Unlimited access to technical support, training, and software updates is included with your purchase.

CONNECTED SYSTEMS

Allows integration to your existing business systems to deliver and access manufacturing data in real-time.

PLATFORM

KÜRSÜLÜ PLATFORM

The Electric Panel with Platform features a mobile design that can move independently from the bridge. This configuration enhances operator flexibility and ergonomics, allowing control of the cutting process from various positions. Ideal for larger machine setups, it offers safe and efficient operation with improved accessibility and visibility of the cutting area.

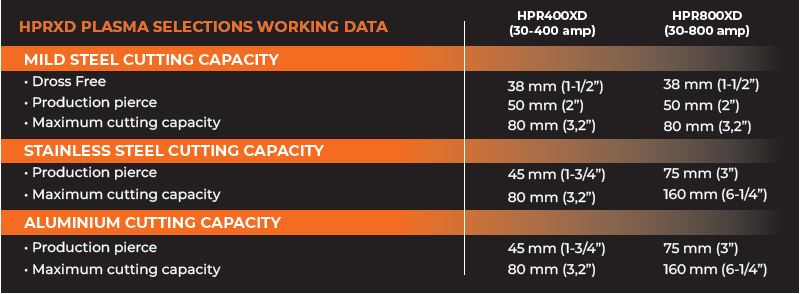

HYPERTHERM HPR400 XD POWER SUPPLY UNIT

HYPERTHERM HPR400 XD GÜÇ KAYNAĞI

INCREASED PARTS PER HOUR

HyPerformance Plasma systems provide faster cut speeds to produce more parts per hour. Hypertherm’s patented PowerPierceTM technology makes it possible to cut thicker than ever before and replace slowercutting technologies such as oxyfuel. HyPerformance Plasma’s superior quality and consistency maximize the number of parts produced per hour by minimizing time-consuming secondary operations.

DO MORE WITH LESS POWER

HyPerformance Plasma enables extremely high cutting speeds per amp with less cutting current than other plasma solutions on the market.

LONGER CONSUMABLE LIFE

LongLife® and PowerPierceTM technologies significantly increase consumable life and reduce your cost per part. Hypertherm consumables are manufactured with the highest quality standards to ensure consistently longer life.

DO MORE WITH LESS POWER

Patented consumable designs enable industry-leading cutting speeds and robust production piercing using lower amperage levels. HyPerformance Plasma enables extremely high cutting speeds per amp with less cutting current than other plasma solutions on the market. Hypertherm’s power supplies are designed to be extremely efficient in their use of electricity, enabling lower electrical expense and a reduced impact on the environment.

HPR400XD® OPERATING DATA

| MILD STEEL CUT CAPACITY | ||

|---|---|---|

| Dross free | 38 mm | (1-1/2”) |

| Production pierce | 50 mm | (2”) |

| Maximum cutting capacity | 80 mm | (3/2”) |

| STAINLESS STEEL CUT CAPACITY | ||

| Production pierce | 45 mm | (1-3/4”) |

| Maximum cutting capacity | 80 mm | (3,2”) |

| ALUMINUM CUT CAPACITY | ||

| Production pierce | 45 mm | (1-3/4”) |

| Maximum cutting capacity | 80 mm | (3,2”) |

POWER SOURCE AND CHILLER

The addition of pump motor drives, fans, and eliminates the effect of frequency on the cooling water flow.

POWER SUPPLY

- Self calibrating current control for better current adjustment.

- High power element/ productivity

- Low fluctuation on exit current for lower arc voltage lapse and more stable plasma arc.

- Serial communication port on CNC for system surveillance.

- CAN serial communication between main modules for system stability.

- Long distance surveillance feature if CNC is connected to network.

MANUAL GAS CONSOLE

- Provides HyDefinition cutting quality with LongLife Technology.

- Compensates for changes in the incoming gas pressure.

- Continuously measures and adjusts the flow of gas.

TORCH

Quick disconnect torch reduces installation time.

OXYCUT – OXY-FUEL CUTTING SYSTEM

OXYCUT – OKSİ-YAKIT KESİM SİSTEMİ

The OXY CUT oxy-fuel cutting system works in harmony with ProNest advanced nesting software, allowing users to program multiple cutting processes efficiently. This provides greater flexibility in production, reduces downtime, and boosts productivity. It is a powerful solution for both single and multi-process cutting applications.

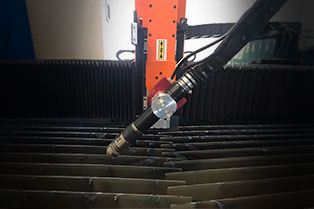

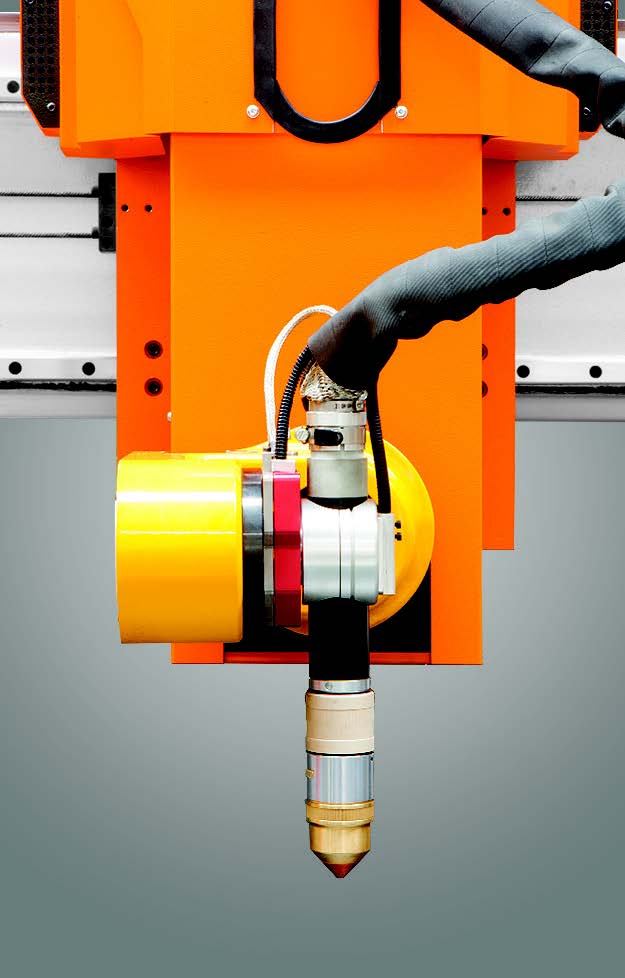

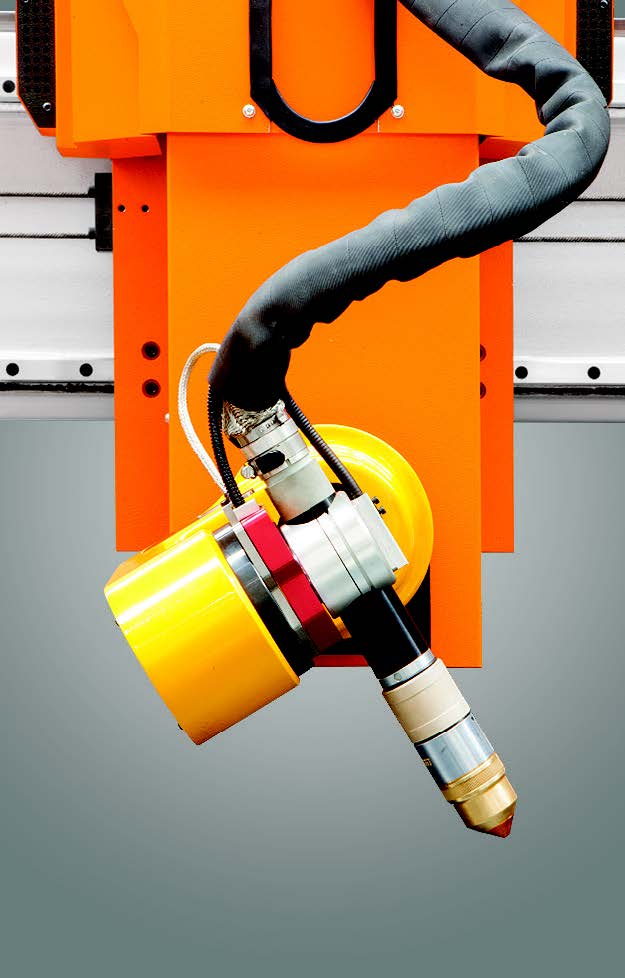

5-AXIS CUTTING HEAD

5 EKSEN KESİM KAFASI

Automatic angle adjustment provides time saving to the operator and removes the issues which could be caused by operator errors.

|

|

|

| Cutting head moves up and down with Z axis right and left with x axis. |

Can move totally +-50 and 60° degrees at A axis. |

Can move totally +-50 and 60° degrees at B axis. |

|

|

|

| 25 mm Mild Steel | 25 mm Mild Steel | 25 mm Mild Steel |

PLATESAVER

PLATESAVER

As part of the SureCut™ technology, PlateSaver™ provides a significant increase in plate savings and profitability.

The enhanced arc stability of the XPR™ X-Definition® plasma allows for shorter cable lengths and closer insertion of parts while quickly stabilizing the plasma torch arc. PlateSaver technology enables the use of new, special-purpose inputs/outputs to the CAM software when scheduling jobs for XPR-equipped machines. Adjusts cable length, style and position, and preserves part quality while using movable drilling to minimize part separation.

Primary advantage

- Lower cost per part due to increased material use

Other advantages can be:

- Less time spent loading and downloading plates

- Less inventory and inventory management

- Reduced carbon footprint thanks to the use of less black sheet metal

Placement with PlateSaver technology

PlateSaver™ is most effective when placing square or rectangular parts, and least effective when placing circular parts . Therefore, depending on your piece mix, PlateSaver will have a huge impact on your material usage . The following example shows square pieces that produce an improvement as high as 14 percentage points:

For jobs involving a mix of differently shaped parts, PlateSaver will achieve an average improvement of 3 percentage points, which is again an impressive rate, and offer significantly lower annual material savings, lower cost per part and higher profitability:

Technical specifications

- Black sheet only, for use with X-Y cutting

- Applies to selected material thickness between 13 mm and 32 mm and suitable plasma treatment combinations

- Requires XPR™ X-Definition® plasma system with convenient CAM software and CNC software

- important: the technique of moving drilling can create a safety problem due to more sparks and spray from hot gases; appropriate precautions must be taken to prevent personal injury, fire or equipment damage.

SURECUT

SURECUT

SureCut technology is available as a combination of Hypertherm's products, such as automation systems, CNCs, and CAM software.

Material type, thickness, cutting type, ampere levels, gas selection and many other factors have an impact on system settings.

An experienced operator can choose the right settings, but in any case the process is based on a bit of trial/error. SureCut saves time by eliminating this trial/error process. Automatically increases productivity exponentially with minimal operator intervention.

The benefits offered by SureCut Technology include: True Hole for bolt-ready holes, True Bevel® for simplifying the process of cutting beveled ™ edges, Rapid Part for significantly reducing cut-cut cycle time and Remote Help® for real-time fault detection™.

RAPID PART

RAPID PART

Achieve greater efficiency by reducing the cut-to-cut cycle time. Rapid Part™ controls and optimizes every step in the plasma cutting process without the need for operator intervention, allowing you to focus on your business and customers.

- Increases the number of hourly parts production by up to 100%.

- Automatically reduces cut-to-cut cycle time without requiring operator intervention.

Less cut-to-cut cycle time means more efficiency

- When a 20.3 cm flange is cut, more than half of the time that passes after the operator presses the "go" button is spent on movement between the cuts when competing THCs are used.

- Rapid Part technology, part of Hypertherm's SureCut™ technology, reduces cut-to-cut cycle time by up to 80% and cutting time for each part by up to 50%.

HYPERTHERM XPR460 POWER SOURCE

HYPERTHERM XPR460 GÜÇ KAYNAĞI

Part of the Hypertherm XPR® family, the XPR460 delivers the most consistent cut quality, thicker cutting capability, and faster cutting speeds in its class increasing productivity and lowering operating costs.

Widest versatility expands capabilities

- Provides superior cutting versatility for mild steel, stainless steel, and aluminum

- Offers the widest range of cutting power for various metals and thicknesses

- Delivers high-quality, consistent cutting on imperfect metal surfaces, including paint and rust

Optimized productivity drives lower operating costs

- Maximum power optimizes productivity by delivering higher cut quality, thicker cutting capability, and faster cutting speeds

- Argon-assist technology enables piercing and edge-starting on the thickest mild steel and stainless steel

- Cuts with oxygen up to 460 amps, delivering the best cutting outcomes on mild steel

- Exclusive Arc Response Technology™ intervenes in adverse events to preserve consumable life and prevent torch damage

Precision cutting reduces secondary operations

- Delivers excellent part-to-part consistency over consumable life from the first cut to the last

- Provides a smooth surface, low angularity, and minimal to no dross for clean parts off the table

- XPR embedded technology improves 45° bevel cut quality on thick material making the welding process more efficient

- Exclusive SureCut™ technology delivers improved outcomes by automatically embedding advanced cutting capabilities into our plasma cutting process

| Mild Steel | mm | inches |

|---|---|---|

| Production pierce capacity | 50 | 2 |

| Enhanced pierce capacity (argon-assist piercing)* | 64 | 2.5 |

| Production severance | 90 | 3.5 |

| Enhanced severance (argon-assist cutting)* | 102 | 4 |

| Stainless Steel | ||

| Production pierce capacity | 38 | 1.5 |

| Enhanced pierce capacity (argon-assist piercing)* | 63 | 2.5 |

| Production severance | 90 | 3.5 |

| Enhanced severence (argon-assist cutting)* | 130 | 5 |

| Aluminum | ||

| Production pierce capacity (N2 shield gas) | 38 | 1.5 |

| Enhanced pierce capacity (argon-assist piercing)* | 63 | 2.5 |

| Production severance | 80 | 3 |

* Delivers excellent part-to-part consistency over consumable life from the first cut to the last

CORE PLUS CONSOL

CORE PLUS KONSOL

This includes particularly good results on thin stainless steel through the Hypertherm HDi cutting process. As the other XPR gas consoles, the CorePlus console can be fully controlled through the CNC for high productivity and ease of use.

VENTED WATER INJECTION (VWI) KONSOL

VENTED WATER INJECTION (VWI) KONSOL

You can add other angles and land dimensions within the specified ranges into the bevel process parameter tables for more flexibility. The tables automatically provide newly calculated output values for angle compensation, kerf, cut height, cut speed, and arc voltage.

FILTERING UNIT

EMİŞ ÜNİTESİ

Filtering unit is designed specially for filtering the gas and particles. With this unit the dirty dust is removed, leaning a safe & clean working environment.

- Clean working ambiance

- Integrated burr separator inhibiting sparks and heavy particles to Reach into the filtering unit during cutting

- 99.9% filtration efficiency according to EN 60335/2/69

- Synchronized automatic start and stop from CNC cutting frame as command